- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-10 Origin: Site

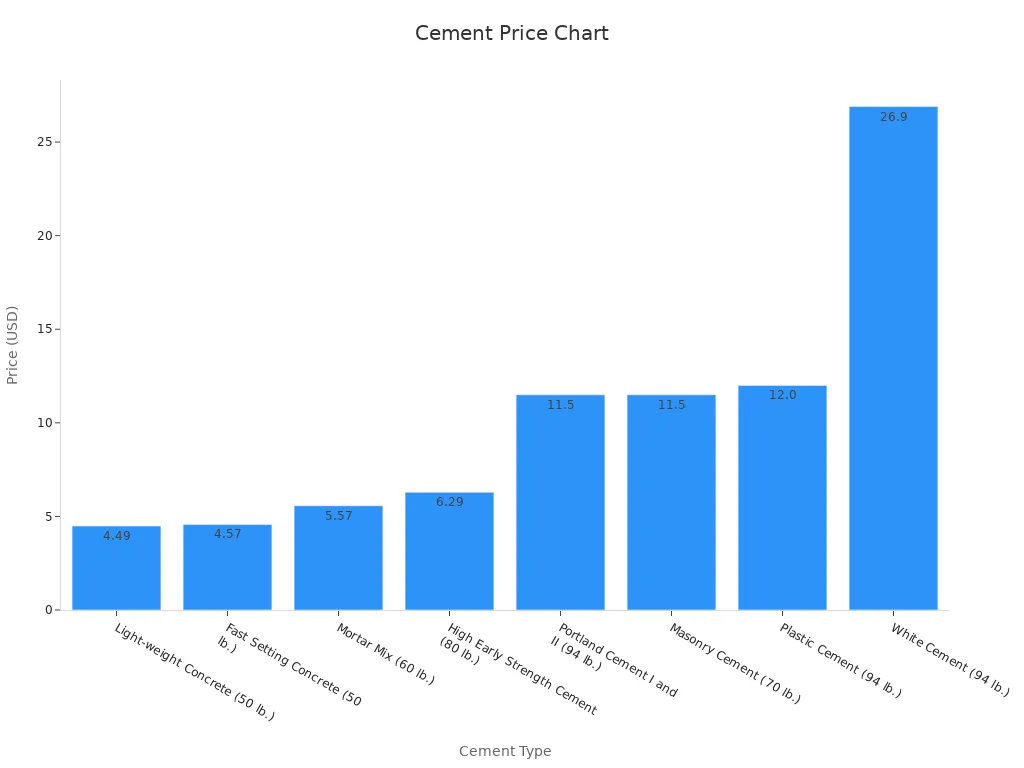

Cement bag cost in the US typically ranges from $4.49 for a 50-pound light-weight concrete bag to $26.90 for a 94-pound white cement bag. Common sizes include 10, 47, 50, 80, and 94 pounds. Prices shift based on brand, retailer, and region. The following table displays recent average prices:

| Cement Type | Average Price per Bag (USD) |

|---|---|

| Light-weight concrete (50 lbs) | $4.49 |

| Fast-setting concrete (50 lbs) | $4.57 |

| Mortar mix (60 lbs) | $5.57 |

| High early strength cement (80 lbs) | $6.29 to $6.65 |

| Portland cement I and II (94 lbs) | $11.50 |

| Masonry cement (70 lbs) | $11.50 |

| Plastic cement (94 lbs) | $12.00 |

| White cement (94 lbs) | $26.90 |

Cement bag prices in the US range from about $4.49 to $26.90 depending on bag size, type, and brand.

Buying in bulk lowers the cost per bag and helps avoid delays in large projects.

Prices vary by region due to transportation, demand, and local taxes, with the West and Northeast generally more expensive.

Big box stores, local suppliers, online retailers, and direct manufacturers offer different prices and buying experiences.

Comparing prices across stores and considering delivery fees can save money and improve convenience.

Seasonal sales, coupons, and loyalty programs provide extra opportunities to reduce cement costs.

Understanding the difference between cement and concrete helps buyers plan budgets accurately.

Proper storage and checking return policies protect buyers from losing money on unused or damaged cement bags.

Cement comes in several standard bag sizes, each serving different project needs. The cost of each bag depends on its weight, type, and the retailer.

A 94-pound bag is the industry standard for Portland cement. Home Depot lists a 94 lb. Portland cement bag at $13.97. Bedrock Landscape Supply offers the same size for $12.00. ECT Manufacturing provides bulk pricing, selling 70 bags at $32.04 per bag, which includes delivery and handling. This size is common for large-scale construction and commercial projects.

An 80-pound bag is popular for both professional and DIY use. Home Depot sells an 80 lb. Quikrete Concrete Mix for $6.29. Walmart’s price for a similar Sakrete product is $6.65. This size works well for medium-sized jobs, such as patios or walkways.

A 50-pound bag is ideal for smaller repairs and home improvement tasks. Home Depot offers a 50 lb. Quikrete Fast-Setting Concrete Mix for $4.57. Walmart lists a 50 lb. Sakrete Concrete Mix at $4.49. These bags are easy to handle and transport.

A 10-pound bag suits minor repairs or craft projects. Home Depot’s 10 lb. Quikrete Concrete Mix costs $2.98. Walmart’s price for a similar product is $3.29. This size is convenient for patching or anchoring small fixtures.

The brand of cement affects both quality and price. Major brands include Quikrete, Sakrete, and Portland Cement. Each brand offers a range of products for different applications.

Quikrete is a leading brand in the US. Home Depot sells a 50 lb. Quikrete Fast-Setting Concrete Mix for $4.57 and an 80 lb. bag for $6.29. Quikrete products are widely available and trusted for consistent performance.

Sakrete offers similar products at competitive prices. Walmart lists a 50 lb. Sakrete Concrete Mix at $4.49. The 80 lb. Sakrete High Strength Concrete Mix is available at Home Depot for $6.65. Sakrete is known for its reliability and is often chosen for both residential and commercial projects.

Portland cement forms the base for most concrete mixes. Home Depot’s 94 lb. Portland Cement Type I/II costs $13.97. Bedrock Landscape Supply offers the same size for $12.00. ECT Manufacturing provides bulk pricing, with 70 bags of 94 lb. Portland cement at $32.04 per bag, which includes delivery. This type is essential for structural work and large pours.

Note: Prices can fluctuate based on supply chain conditions, energy costs, and regional demand. According to recent market data, the average cement price in the USA stands at $106 per metric ton, driven by high capacity utilization and strong commercial construction demand. Regional price trends show slight decreases in North America, but local factors may cause short-term spikes.

| Retailer | 10 lb. | 50 lb. | 80 lb. | 94 lb. |

|---|---|---|---|---|

| Home Depot | $2.98 | $4.57 | $6.29 | $13.97 |

| Walmart | $3.29 | $4.49 | $6.65 | N/A |

| Bedrock Landscape Supply | N/A | N/A | N/A | $12.00 |

| ECT Manufacturing (Bulk) | N/A | N/A | N/A | $32.04 (bulk, 70 bags) |

The cement bag cost generally ranges from $10 to $36 per bag, depending on size, brand, and purchase quantity. Bulk orders often provide significant savings, especially for large projects. Market reports from IMARC Group highlight that input costs, supply-demand imbalances, and regional construction activity all influence these prices. For example, rising energy costs and high demand in the US have pushed prices higher, while oversupply in other regions has led to declines.

Tip: Buyers should compare prices across retailers and consider bulk purchasing for the best value. Local suppliers may offer lower delivery fees or discounts for large orders.

Location plays a major role in determining the cost of cement. Prices often vary between regions due to transportation costs, local demand, and proximity to manufacturing plants. For example, buyers in urban areas with high construction activity may see higher prices because of increased demand. In contrast, rural regions might experience lower prices if they are close to a cement plant, but remote areas can face higher costs due to shipping expenses.

Retailers in the Northeast and West often charge more for cement than those in the Midwest or South. This difference results from factors such as local taxes, labor rates, and the cost of raw materials. Weather also impacts pricing. Areas with harsh winters may see seasonal price increases as construction ramps up in spring and summer.

Tip: Buyers should check local suppliers and compare prices in nearby cities. Sometimes, crossing a county line can lead to significant savings on cement.

Brand selection influences both the quality and price of cement. Well-known brands like Quikrete, Sakrete, and Portland Cement often command higher prices because of their reputation for consistency and performance. These brands invest in quality control and product innovation, which adds to production costs.

Lesser-known or store brands may offer lower prices, but they might not meet the same standards for strength or durability. Contractors and professionals usually prefer established brands for large projects, while homeowners might choose generic options for small repairs. Brand loyalty can also affect purchasing decisions, especially when a specific product has proven reliable in past projects.

A comparison of popular brands shows that Quikrete and Sakrete often have similar pricing, but regional availability can shift the balance. Portland Cement, used as a base for many mixes, tends to have a stable price across most retailers.

The amount of cement purchased directly affects the price per bag. Buying in bulk usually leads to lower unit costs. Suppliers often provide discounts for large orders, especially for commercial projects or contractors. For example, purchasing a pallet of 70 bags can reduce the price per bag by several dollars compared to buying single bags.

Bulk pricing benefits not only large construction firms but also homeowners planning extensive renovations. Some retailers offer special deals or free delivery for bulk purchases. However, buyers should consider storage space and shelf life before ordering large quantities.

When evaluating concrete price considerations, buyers should factor in both the immediate cost per bag and potential savings from bulk orders. Planning ahead can help maximize value and reduce overall project expenses.

The type of store where buyers purchase cement bags plays a significant role in determining the final price. Different retailers have unique pricing strategies, overhead costs, and customer service levels. These factors influence the cost per bag and the overall value for the customer.

Big Box Stores

Large chains like Home Depot and Lowe’s often offer competitive prices due to their high sales volume. They negotiate bulk deals with manufacturers, which allows them to pass savings on to customers. These stores usually provide a wide selection of brands and bag sizes. Shoppers benefit from frequent promotions and loyalty programs. However, prices may vary by location, and some stores charge extra for delivery.

Local Suppliers

Local building supply stores or landscape yards may set higher prices per bag. They often focus on personalized service and may offer flexible delivery options. Local suppliers sometimes provide discounts for repeat customers or contractors. Their proximity can reduce transportation costs, especially for buyers located far from big box stores.

Online Retailers

Online platforms like Amazon or Walmart.com provide convenience and access to a broad range of products. Prices can fluctuate based on shipping fees and third-party seller markups. Some online retailers offer free shipping for bulk orders, but buyers should check return policies and delivery times.

Direct from Manufacturer

Purchasing directly from a cement manufacturer can yield the lowest price per bag, especially for large projects. Manufacturers may require minimum order quantities. This option suits contractors or businesses rather than individual homeowners.

Note: Buyers should compare prices across different store types. Factoring in delivery fees, return policies, and customer support helps ensure the best value for each project.

The Northeast region often reports some of the highest cement prices in the United States. This area includes states like New York, Massachusetts, and Pennsylvania. High population density and strong demand for construction materials drive up costs. Transportation expenses also play a role. Many cement plants are located far from major cities in this region, which increases shipping fees.

Retailers in the Northeast typically charge between $13 and $20 for a 94-pound bag of cement. Smaller bags, such as 50-pound options, usually cost $5 to $7. Local taxes and higher labor rates contribute to these elevated prices. Seasonal demand spikes in spring and summer can cause temporary price increases. Contractors in cities like Boston and New York City often pay a premium compared to those in rural areas.

Note: Buyers in the Northeast should compare prices at both big box stores and local suppliers. Sometimes, local yards offer better deals on bulk orders.

The Midwest features some of the most stable cement prices in the country. States like Illinois, Ohio, and Michigan benefit from proximity to major cement manufacturing plants. Shorter transportation routes help keep costs lower. The region’s moderate demand and steady supply chain also support price stability.

A 94-pound bag of cement in the Midwest usually costs between $11 and $15. The 50-pound bags often range from $4.50 to $6. Retailers in cities like Chicago and Detroit offer competitive pricing, especially for bulk purchases. Many local suppliers provide discounts for contractors and repeat customers.

The Midwest’s central location allows for efficient distribution. This advantage helps keep the nationwide concrete cost more balanced. Homeowners and builders in this region often find it easier to plan projects without worrying about sudden price jumps.

The South covers states such as Texas, Florida, and Georgia. This region experiences moderate to low cement prices compared to other parts of the country. Warm weather allows for year-round construction, which helps maintain steady demand. Many cement plants operate in the South, reducing transportation costs for local buyers.

A 94-pound bag of cement in the South generally sells for $12 to $16. The 50-pound bags typically cost $4.50 to $6.50. Retailers in cities like Houston and Atlanta often run seasonal promotions, especially during peak building months. Local suppliers may offer additional savings for large orders or repeat business.

Tip: Buyers in the South should watch for seasonal sales and consider bulk purchasing to maximize savings.

Regional differences in cement pricing reflect local market conditions, transportation logistics, and supply chain factors. Comparing prices across regions helps buyers understand how the nationwide concrete cost can vary from state to state.

The West region of the United States covers states such as California, Washington, Oregon, Nevada, and Arizona. This area often experiences higher cement prices compared to other regions. Several factors contribute to this trend. High transportation costs, strict environmental regulations, and strong demand in urban centers all play a role.

California stands out as a state with some of the highest cement prices in the country. Retailers in Los Angeles and San Francisco often charge between $15 and $22 for a 94-pound bag. Smaller bags, such as the 50-pound size, usually range from $5.50 to $7.50. The Pacific Northwest, including Washington and Oregon, also sees elevated prices. These states rely on shipments from distant manufacturing plants, which increases delivery expenses.

Note: Environmental policies in the West can affect cement production costs. Regulations on emissions and energy use often lead to higher prices for both manufacturers and consumers.

Nevada and Arizona offer slightly lower prices than California. In cities like Las Vegas and Phoenix, a 94-pound bag of cement typically costs $13 to $17. The 50-pound bags usually fall between $5 and $6.50. Proximity to regional cement plants helps keep prices more stable in these states.

The West also faces unique challenges with supply chain disruptions. Wildfires, droughts, and port delays can impact the availability of cement. When supply drops, prices may spike temporarily. Contractors and homeowners in this region should monitor local market conditions before starting large projects.

A quick comparison of average cement prices in the West:

| State | 94 lb. Bag | 50 lb. Bag |

|---|---|---|

| California | $15–$22 | $5.50–$7.50 |

| Washington | $14–$19 | $5.50–$7.00 |

| Oregon | $14–$18 | $5.50–$7.00 |

| Nevada | $13–$17 | $5.00–$6.50 |

| Arizona | $13–$17 | $5.00–$6.50 |

Buyers in the West should compare prices at both big box stores and local suppliers. Shopping around can help offset higher cement costs in this region.

Big box stores such as Home Depot, Lowe’s, and Walmart serve as primary sources for cement bags in the United States. These retailers offer a wide selection of brands and bag sizes. Shoppers often find Quikrete, Sakrete, and Portland cement products on their shelves. Home Depot and Lowe’s maintain consistent pricing across most locations, which helps buyers plan budgets with confidence. Walmart provides competitive prices, especially for smaller bag sizes.

Customers benefit from frequent promotions and loyalty programs at these stores. Many locations offer in-store pickup and local delivery services. Home Depot, for example, allows customers to order online and pick up in-store within a few hours. Lowe’s provides similar convenience, with options for curbside pickup. These features save time and reduce transportation costs for buyers.

Tip: Shoppers should check weekly ads and online deals. Big box stores often run seasonal sales, especially during spring and summer construction peaks.

The main advantage of big box stores lies in their accessibility and inventory. Most urban and suburban areas have at least one location nearby. These stores also provide return policies that protect buyers if they purchase too much material.

Local building supply stores and landscape yards offer another reliable source for cement bags. These businesses often focus on serving contractors, builders, and homeowners in their immediate area. Local suppliers may carry specialty cement products not found at national chains. They sometimes stock regional brands that cater to specific climate or soil conditions.

Prices at local suppliers can vary. Some charge slightly more per bag than big box stores, but they may offset this with personalized service and flexible delivery options. Many local suppliers offer discounts for repeat customers or bulk purchases. Contractors often build relationships with these businesses, which can lead to better pricing and priority service during busy seasons.

Local suppliers usually have knowledgeable staff who can answer technical questions. They help buyers select the right product for their project. This expertise proves valuable for complex jobs or when using cement in unique applications.

Note: Buyers should ask about delivery fees and minimum order requirements. Local suppliers sometimes waive these fees for large orders or regular customers.

Online retailers provide a convenient way to purchase cement bags without leaving home. Websites such as Amazon, Walmart.com, and HomeDepot.com list a variety of cement products. Shoppers can compare prices, read reviews, and check availability with just a few clicks.

Online platforms sometimes offer exclusive deals or free shipping for bulk orders. However, shipping heavy items like cement can add significant costs. Buyers should review delivery times and return policies before placing an order. Some online retailers partner with local stores for same-day pickup or delivery.

The main advantage of online shopping is convenience. Buyers can place orders at any time and have materials delivered directly to their job site. This option works well for those who live far from physical stores or need to coordinate deliveries for large projects.

| Retailer | In-Store Pickup | Delivery | Bulk Discounts | Return Policy |

|---|---|---|---|---|

| Home Depot | Yes | Yes | Yes | Yes |

| Lowe’s | Yes | Yes | Yes | Yes |

| Walmart | Yes | Yes | Limited | Yes |

| Amazon | No | Yes | Limited | Varies |

| Local Supplier | Varies | Yes | Yes | Varies |

Tip: Always compare total costs, including shipping and delivery fees, before making a purchase online.

Purchasing cement bags directly from the manufacturer offers a unique option for buyers with large-scale needs. This approach appeals mostly to contractors, construction companies, and businesses that require significant quantities of cement. Homeowners rarely use this method unless they plan a major project, such as building a house or undertaking extensive renovations.

Manufacturers like LafargeHolcim, CEMEX, and Lehigh Hanson operate cement plants across the United States. These companies sell their products in bulk, often requiring a minimum order—sometimes a full pallet or truckload. Buyers must contact the manufacturer’s sales department or authorized distributor to request a quote. The process usually involves providing details about the project, delivery location, and desired quantity.

Advantages of Buying Direct:

Lower Unit Cost: Manufacturers offer the best price per bag for bulk orders. Large purchases eliminate retail markups.

Consistent Supply: Direct orders ensure access to fresh stock and reduce the risk of shortages during peak construction seasons.

Custom Orders: Some manufacturers allow buyers to request specific cement types or custom blends for specialized projects.

Potential Drawbacks:

High Minimum Orders: Most manufacturers set a minimum purchase requirement, often much higher than retail stores.

Complex Logistics: Buyers must arrange for delivery, unloading, and storage. Manufacturers may charge extra for shipping, especially for remote locations.

Limited Flexibility: Returns or exchanges can be difficult. Manufacturers rarely accept small returns or partial pallets.

Tip: Contractors should compare direct pricing with local suppliers and big box stores. Sometimes, local distributors offer similar bulk discounts with easier logistics.

The following table summarizes the key differences between buying direct and other options:

| Buying Option | Best For | Price Per Bag | Minimum Order | Delivery Options | Returns |

|---|---|---|---|---|---|

| Direct from Manufacturer | Large projects, contractors | Lowest (bulk) | High | Arranged by buyer/manufacturer | Limited |

| Big Box Store | Homeowners, small jobs | Moderate | Low (single bag) | In-store/Local delivery | Flexible |

| Local Supplier | Contractors, repeat buyers | Competitive | Medium | Local delivery | Varies |

| Online Retailer | Remote buyers, convenience | Varies | Low–Medium | Shipped to site/home | Varies |

Manufacturers focus on efficiency and scale. They design their sales process for buyers who need hundreds or thousands of bags. For most residential projects, big box stores or local suppliers remain the better choice. However, for commercial builds or community developments, buying direct can deliver significant savings and reliability.

Buyers should always request detailed quotes and clarify delivery terms before placing a direct order. This step helps avoid unexpected costs and ensures the cement arrives on schedule.

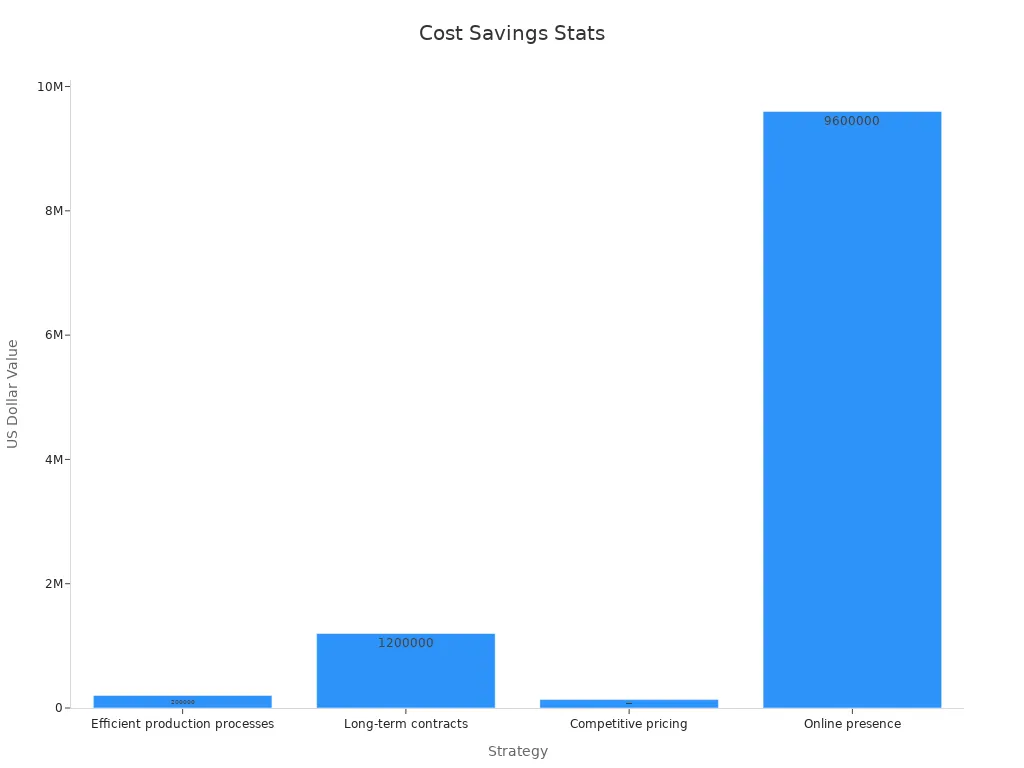

Bulk purchasing stands out as one of the most effective ways to lower the cost per cement bag. Suppliers often provide significant discounts for large orders, especially when buyers purchase by the pallet or truckload. Contractors and organizations with ongoing projects benefit the most from this approach. Homeowners planning major renovations can also take advantage of these savings.

Bulk transport reduces logistics costs. When cement moves in large quantities, especially by sea or rail, the cost per bag drops. The following table highlights how logistics and distribution impact cement pricing:

| Aspect | Data/Value |

|---|---|

| Logistic cost per 50-kg bag by road | Rs 18–25 |

| Logistic cost per 50-kg bag by railway | Rs 12–15 |

| Distribution cost as % of cement price | 30–35% |

| Cement moved worldwide by sea (bulk) | 70% |

| Selling/distribution costs as % of revenue | 18% |

Bulk movement by sea covers 70% of global cement transport, showing the scale and efficiency of large shipments. Distribution and logistics can make up to 35% of the total cement cost. Buyers who order in bulk often see these savings reflected in lower prices per bag.

Tip: Buyers should coordinate with neighbors or local contractors to combine orders. This strategy helps smaller buyers access bulk rates.

Cement prices often fluctuate with the seasons. Retailers typically offer discounts during slower construction periods, such as late fall or winter. These sales help stores clear inventory before demand rises in spring and summer. Shoppers who plan ahead can take advantage of these seasonal promotions.

Many big box stores and local suppliers advertise sales in their weekly flyers or online. Contractors often schedule large purchases during these periods to maximize savings. Homeowners can also benefit by buying cement in advance for planned projects.

Planning purchases around seasonal sales can lead to substantial savings, especially for those with flexible project timelines.

Comparing prices across different retailers remains a simple but powerful way to save money on cement bags. Big box stores, local suppliers, and online retailers often list different prices for the same product. Some stores offer loyalty programs or price matching, which can further reduce costs.

A quick price check at several stores can reveal significant differences. For example, one retailer may offer a lower base price, while another provides free delivery or bulk discounts. Buyers should also consider return policies and customer service when making their choice.

Make a list of nearby suppliers.

Check online prices and in-store promotions.

Ask about bulk discounts and delivery fees.

Smart shoppers compare at least three sources before making a purchase. This habit ensures the best value for every project.

Many retailers offer coupons that help buyers save money on cement bags. Shoppers can find these discounts in several places. Home improvement stores like Home Depot and Lowe’s often provide digital coupons on their websites or mobile apps. Some stores send out paper coupons in local newspapers or through direct mail. Buyers should check the weekly ads before heading to the store.

Online coupon websites also list current deals for major retailers. Sites such as RetailMeNot, Coupons.com, and Honey collect and update codes regularly. Shoppers can search for “cement bag coupon” or the specific store name to find the latest offers. Signing up for store newsletters can also unlock exclusive discounts and early access to sales.

Tip: Always read the coupon’s terms and conditions. Some coupons apply only to certain brands or bag sizes. Others may require a minimum purchase amount.

Loyalty programs provide another way to save. Many big box stores reward frequent buyers with points or special discounts. For example, Home Depot’s Pro Xtra program gives members access to bulk pricing and occasional coupons. Lowe’s MVPs Pro Rewards offers similar benefits. Contractors and regular buyers should enroll in these programs to maximize savings.

A quick checklist for using coupons effectively:

Search for digital and paper coupons before shopping.

Sign up for retailer newsletters and loyalty programs.

Check expiration dates and restrictions.

Combine coupons with sales or bulk discounts when possible.

Coupons may not always provide huge savings, but every dollar counts, especially for large projects. Smart shoppers stack coupons with other offers to get the best deal.

Choosing between delivery and pickup can impact the total cost of cement bags. Each option has its own advantages and potential savings. Buyers should consider their project size, location, and transportation resources.

Pickup

Most big box stores and local suppliers allow customers to pick up cement bags directly. This method eliminates delivery fees. Shoppers can inspect the product before leaving the store. Pickup works best for small to medium projects or when buyers have access to a truck or trailer.

Delivery

Delivery offers convenience, especially for large or heavy orders. Many retailers provide home or job site delivery for an extra fee. Some stores offer free delivery if buyers meet a minimum purchase amount. Delivery saves time and effort, but buyers should factor in the added cost.

| Option | Pros | Cons |

|---|---|---|

| Pickup | No delivery fee, immediate access | Requires transport, labor |

| Delivery | Convenient, saves time/effort | Extra fee, delivery window |

Note: Buyers should compare the total cost, including delivery fees, before making a decision. For large projects, delivery may be worth the extra expense. For smaller jobs, pickup usually offers better value.

Some stores allow customers to order online and choose in-store or curbside pickup. This hybrid option combines convenience with cost savings. Buyers can schedule pickup times and avoid waiting in line.

Smart planning helps buyers avoid unnecessary expenses. By weighing the pros and cons of delivery versus pickup, shoppers can choose the best option for their budget and project needs.

The cost of concrete in the United States depends on several factors, but most buyers see a range between $60 and $150 per cubic yard. This price includes not only cement but also aggregates, water, admixtures, and labor for mixing and pouring. The concrete cost per yard reflects both material and delivery expenses. For residential projects, the average cost of concrete typically falls near the lower end of the range, while large commercial jobs or specialty mixes can push prices higher.

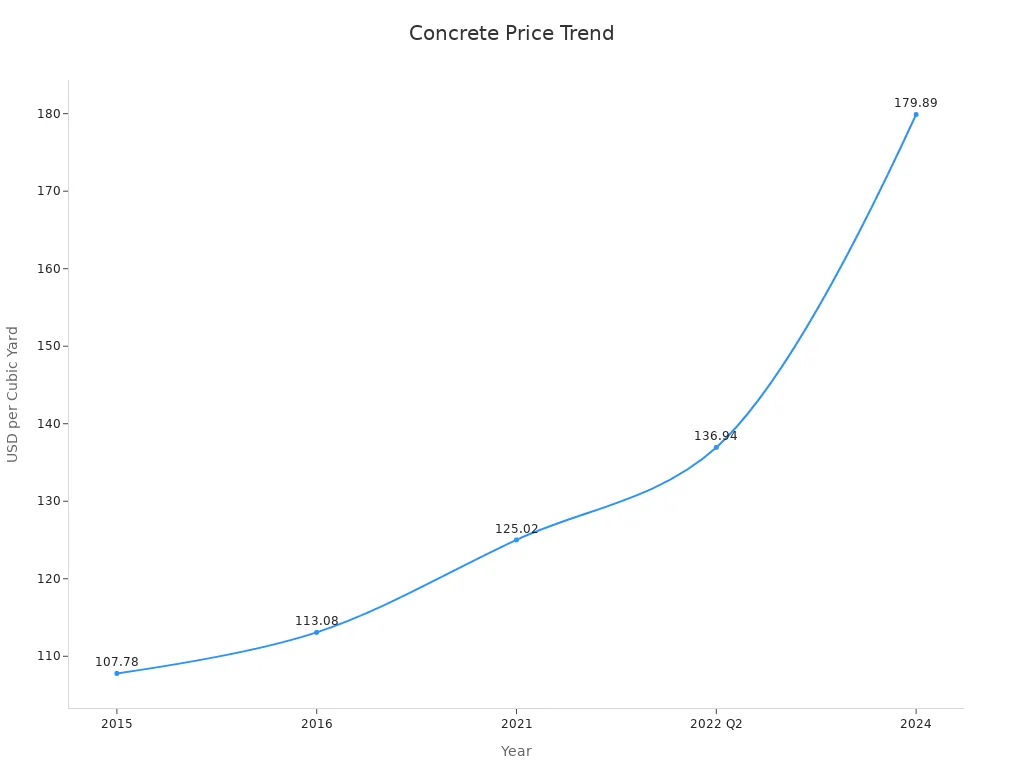

Recent industry data shows a steady increase in concrete cost per yard over the past decade. In 2015, the average price per cubic yard stood at about $108. By 2024, this figure reached nearly $180 per cubic yard, representing a 6% cumulative average growth rate since 2016. The following table summarizes these trends:

| Year | Average Price per Cubic Yard (USD) | Notes on Regional/Seasonal Variations |

|---|---|---|

| 2015 | ~$107.78 | Construction season length varies by region |

| 2016 | $113.08 | Weighted average price from major companies |

| 2021 | $125.02 | Price increases lag input cost inflation |

| 2022 Q2 | $136.94 | 10% YoY price increase, regional price mix affects seasonality |

| 2024 | $179.89 | Prices higher for large commercial/infrastructure projects |

Concrete cost per yard can fluctuate due to input costs, such as diesel fuel and cement. For example, tariffs on imported cement have pushed cement prices from $130 to $162 per ton, which increases the overall cost of concrete.

Concrete prices per yard vary across the country. In regions with long construction seasons, such as the South and West, the average cost of concrete may remain stable for most of the year. In contrast, the Northeast and Midwest often see seasonal price spikes during peak building months. Transportation costs, local demand, and proximity to suppliers also influence concrete cost per yard.

The following table highlights recent trends in concrete pricing and market fluctuations:

| Date | Concrete Cost Trend / Data Point |

|---|---|

| April 2025 | Concrete prices stable quarter-to-quarter; 0.84% increase since Q2 2024 |

| January 2025 | Concrete costs dipped 1.65% from Q4 2024 but up 6.7% year-over-year |

| October 2024 | Concrete block prices increased after 15% rise since end of 2023 due to shortages |

| July 2024 | Concrete block costs steady after two quarters of 5%+ growth |

| April 2024 | Significant price increases in concrete and masonry categories |

Regional differences in concrete cost per yard reflect both supply chain challenges and local market conditions. Areas that rely heavily on imported cement may experience higher prices and occasional delays.

Cement and concrete are not the same, though many people use the terms interchangeably. Cement acts as a key ingredient in concrete, serving as the binder that holds the mix together. Concrete combines cement with sand, gravel, water, and sometimes additives to create a strong, durable building material.

The cost of concrete includes more than just cement. It covers aggregates, labor, transportation, and finishing. For example, the average cost of concrete slab installation ranges from $4 to $8 per square foot, with reinforced concrete reaching up to $10 per square foot. In contrast, cement alone represents only a portion of the total expense.

Cement is a critical input for concrete production.

Concrete cost per yard reflects the sum of all materials, labor, and delivery.

Market forces, such as tariffs and supply shortages, can impact both cement and concrete prices.

| Cost Category | Price per Square Foot (USD) |

|---|---|

| Low-end Concrete Slab | $4.00 |

| High-end Concrete Slab | $8.00 |

| National Average | $6.60 |

| Reinforced Concrete | $9.29 - $10.04 |

Understanding the difference between cement and concrete helps buyers make informed decisions. The cost of concrete will always exceed the price of cement bags due to the added value of mixing, transporting, and placing the finished product.

Cement bag prices in the United States often change due to several factors. Manufacturers adjust prices based on raw material costs, energy prices, and transportation expenses. Supply chain disruptions, such as port delays or fuel shortages, can also cause sudden price increases. Regional demand plays a role as well. For example, construction booms in certain areas may lead to higher prices.

Retailers update their prices to reflect these changes. Big box stores and local suppliers may adjust prices monthly or even weekly during periods of high volatility. Buyers should monitor market trends and check prices regularly before making large purchases.

Tip: Buyers can sign up for price alerts from major retailers or use online tools to track price changes over time.

A summary of recent price trends:

| Year | Average Price per 94 lb. Bag | Notable Factors |

|---|---|---|

| 2022 | $12.50 | High demand, fuel costs |

| 2023 | $13.25 | Supply chain issues |

| 2024 | $13.97 | Stable, minor increases |

Some buyers look for alternatives to traditional cement to save money. Several options exist, each with its own benefits and limitations.

Blended Cement: Manufacturers mix Portland cement with fly ash, slag, or other materials. This blend often costs less and reduces environmental impact.

Masonry Cement: For non-structural projects, masonry cement provides a lower-cost option. It works well for bricklaying or stucco.

Recycled Concrete: Crushed concrete from demolished structures can serve as a base material for new projects. This option reduces waste and lowers costs.

Soil-Cement: Mixing soil with a small amount of cement creates a strong base for driveways or walkways. This method uses less cement and saves money.

Note: Not all alternatives suit every project. Buyers should consult with a building professional before choosing a substitute.

Estimating the number of cement bags needed for a project helps control costs and avoid waste. The amount depends on the project size, mix type, and bag size.

A simple formula for small concrete projects:

Number of bags = (Cubic feet needed) / (Yield per bag)

For example, an 80 lb. bag of concrete mix yields about 0.6 cubic feet. To pour a 4-foot by 4-foot slab at 4 inches thick:

Area: 4 ft x 4 ft = 16 sq ft

Thickness: 4 inches = 0.33 ft

Volume: 16 sq ft x 0.33 ft = 5.28 cubic feet

Bags needed: 5.28 / 0.6 ≈ 9 bags

Tip: Always round up and buy an extra bag or two for unexpected needs.

Many retailers provide online calculators to help buyers estimate material requirements. Accurate estimates save money and reduce leftover material.

Returning cement bags can present unique challenges. Most retailers accept returns, but policies differ based on the store type, product condition, and purchase method. Buyers should understand these rules before making a purchase, especially for large or custom orders.

Key Points to Know About Cement Bag Returns:

Condition Matters:

Retailers usually require cement bags to remain unopened and in original packaging. Damaged or opened bags often do not qualify for returns. Moisture exposure can ruin cement, so stores inspect bags for signs of hardening or clumping.

Time Limits:

Most big box stores, such as Home Depot and Lowe’s, allow returns within 90 days of purchase. Some local suppliers set shorter windows, sometimes only 30 days. Online retailers may have different timelines, especially if third-party sellers handle the order.

Proof of Purchase:

Buyers must present a receipt or order confirmation. Digital receipts from online orders also work. Without proof of purchase, stores may refuse the return or offer only store credit.

Bulk and Special Orders:

Bulk purchases or custom-blended cement often fall under stricter policies. Many suppliers consider these sales final. Buyers should confirm return options before placing large orders.

Tip: Always store cement bags in a dry, protected area until use. Proper storage keeps the product eligible for return if plans change.

Comparison of Return Policies by Retailer Type:

| Retailer Type | Typical Return Window | Condition Required | Restocking Fee | Notes |

|---|---|---|---|---|

| Big Box Store | 90 days | Unopened, undamaged | Rare | Receipt required |

| Local Supplier | 30–60 days | Unopened, undamaged | Possible | Policies vary, ask in advance |

| Online Retailer | 30–90 days | Unopened, undamaged | Possible | Shipping fees may apply |

| Manufacturer Direct | Final sale common | N/A | N/A | Bulk orders rarely returnable |

Steps for a Smooth Return:

Check the store’s return policy before purchase.

Keep all receipts and order confirmations.

Inspect bags upon delivery or pickup for damage.

Store bags off the ground and away from moisture.

Return unused bags within the allowed window.

Buyers who plan ahead and follow these steps reduce the risk of wasted money. They also avoid project delays caused by unusable materials.

Some stores offer store credit instead of refunds, especially for returns without receipts. Others may deduct a restocking fee for large returns. Buyers should clarify these details with the retailer before finalizing a purchase.

Cement is heavy and bulky. For online returns, buyers may need to pay shipping costs. Local returns often require transporting the bags back to the store. Planning for these logistics saves time and effort.

Cement bag prices in the US typically range from $10 to $36, influenced by brand, region, bulk discounts, and transportation. Key factors include:

Bulk orders lower unit costs and help avoid project delays.

Overhead costs and regional price fluctuations affect budgeting.

Comparing multiple suppliers and reviewing bids ensures competitive pricing.

Setting aside 10–15% of the budget covers unexpected expenses.

| Cost-Saving Tip | Statistic / Benefit |

|---|---|

| Accurate material calculation | 91.5% of projects over budget—accurate estimates help |

| Bulk purchasing | Lowers upfront costs and streamlines procurement |

| Prevented delays | Avoids 20–30% project delays and extra costs |

Local suppliers often provide the most current prices. Readers are encouraged to share their own tips or questions in the comments.

Cement bag prices can shift monthly or even weekly. Retailers adjust prices based on supply chain issues, fuel costs, and local demand. Buyers should check prices before each purchase to avoid surprises.

A cement bag typically lasts six to twelve months if stored in a dry, moisture-free area. Exposure to humidity or water can cause the cement to harden and become unusable.

Most retailers accept returns of unopened, undamaged cement bags within a set period. Proof of purchase is usually required. Policies differ by store, so buyers should confirm details before buying.

Yes, manufacturers offer blended cements with fly ash or slag. These products reduce carbon emissions and often cost less than traditional Portland cement. Eco-friendly options suit many non-structural projects.

Buyers can use online calculators or simple formulas. For example:

Bags needed = (Cubic feet required) ÷ (Yield per bag)

Always round up and buy an extra bag to cover unexpected needs.

Not all stores provide bulk discounts. Big box retailers and local suppliers often offer lower prices for pallet or truckload purchases. Buyers should ask about bulk pricing before placing large orders.

Cement acts as a binder in concrete. Concrete combines cement, sand, gravel, and water. Cement alone cannot form strong structures. Concrete provides the strength needed for construction.

Storing cement bags outdoors is not recommended. Moisture and temperature changes can damage the product. Always keep bags in a dry, covered area to maintain quality.