- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-31 Origin: Site

A valve bag making machine is designed to produce specialized bags featuring a self-sealing valve, making it perfect for packaging powders, granules, and pellets. Industries including food and beverage, pharmaceuticals, consumer goods, and various industrial sectors depend on the valve bag making machine for secure, hygienic, and efficient packaging solutions. The packaging industry highly values the valve bag making machine due to its ability to comply with strict safety and sustainability standards. The growing demand for these machines is reflected in the market growth:

| Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

| 2024 | 8.71 | N/A |

| 2025 | 9.39 | 7.8 |

A valve bag is a specialized packaging solution designed for efficient and secure storage of powders, granules, and pellets. Manufacturers create these bags with a unique valve opening, usually located at one corner. This valve allows automated filling machines to insert materials directly into the bag. The design supports high-speed filling and ensures the bag closes automatically after filling, reducing the risk of spillage and contamination.

Valve bags come in various constructions and materials. The most common types include multi-layer kraft paper, polypropylene (PP), polyethylene (PE), and paper-plastic composites. Each material offers specific benefits for different applications. For example, a bag with an inner PP layer and an outer kraft layer provides excellent protection for food and seeds, helping retain freshness. Multi-layer designs enhance durability and moisture resistance, making them suitable for industrial use.

| Material Type | Key Properties | Suitable Applications |

|---|---|---|

| Polypropylene (PP) | High strength, wear resistance | Chemical powders, fertilizers |

| Polyethylene (PE) | Good moisture resistance | Food, medicine packaging |

| Paper-Plastic Composite | Combines plastic strength and paper's environmental benefits | High-value products |

| Kraft Paper | Durable paper, available in various grades | Grains, salt packaging |

The main function of a valve bag is to provide a reliable and efficient packaging method for dry, free-flowing products. Industries use valve bags to package materials such as cement, flour, chemicals, and animal feed. The valve bag making machine produces these bags with a self-sealing valve, which plays a crucial role during the filling process.

The valve opening allows automated filling equipment to insert the product quickly and accurately. As the bag fills, the valve closes automatically, creating a tight seal. This mechanism prevents product loss, reduces dust, and protects the contents from moisture and contaminants. The self-sealing feature eliminates the need for manual sealing, saving time and labor. Valve bags also support neat stacking and firm handling, which is important for storage and transportation.

Note: Valve bags enable high-speed, dust-free filling and minimize product loss, making them ideal for industrial packaging.

Valve bags offer several features that make them popular in bulk packaging:

Unique valve mechanism for easy filling and secure sealing.

Multi-layer construction for enhanced durability and protection.

Tamper-evident sealing to maintain product integrity.

Protection against contamination and moisture, preserving product quality.

Efficient filling and sealing processes that save time and reduce waste.

Neat stacking for improved storage and transportation.

Customizable in size, material, and branding to suit various industries.

Options for recyclable and biodegradable materials, supporting sustainability.

The valve bag making machine uses advanced technology to produce these bags. Key components and mechanisms include:

Material feeding system for continuous supply of raw materials.

Cutting and folding units for precise bag shaping.

Heat sealing technology for strong, durable seals without glue.

Valve applicator for attaching the valve mechanism.

Control system for consistent and accurate production.

Valve bag making machines differ from other bag making machines by using specialized feeding and filling methods. They use impeller, gravity, or screw feeding to handle powdery and granular materials. The valve-mouth filling system ensures precise filling, reducing spillage and waste. Automation levels in these machines improve productivity and minimize downtime, making them suitable for industries that require high accuracy and efficiency.

The self-sealing valve mechanism in valve bags prevents spillage and contamination during filling and transport. The valve closes tightly after filling, creating an airtight seal that protects the contents from moisture, dust, and contaminants. This feature is especially important for products like cement and fertilizers, which are sensitive to moisture. The design also reduces manual handling, lowering labor costs and improving safety.

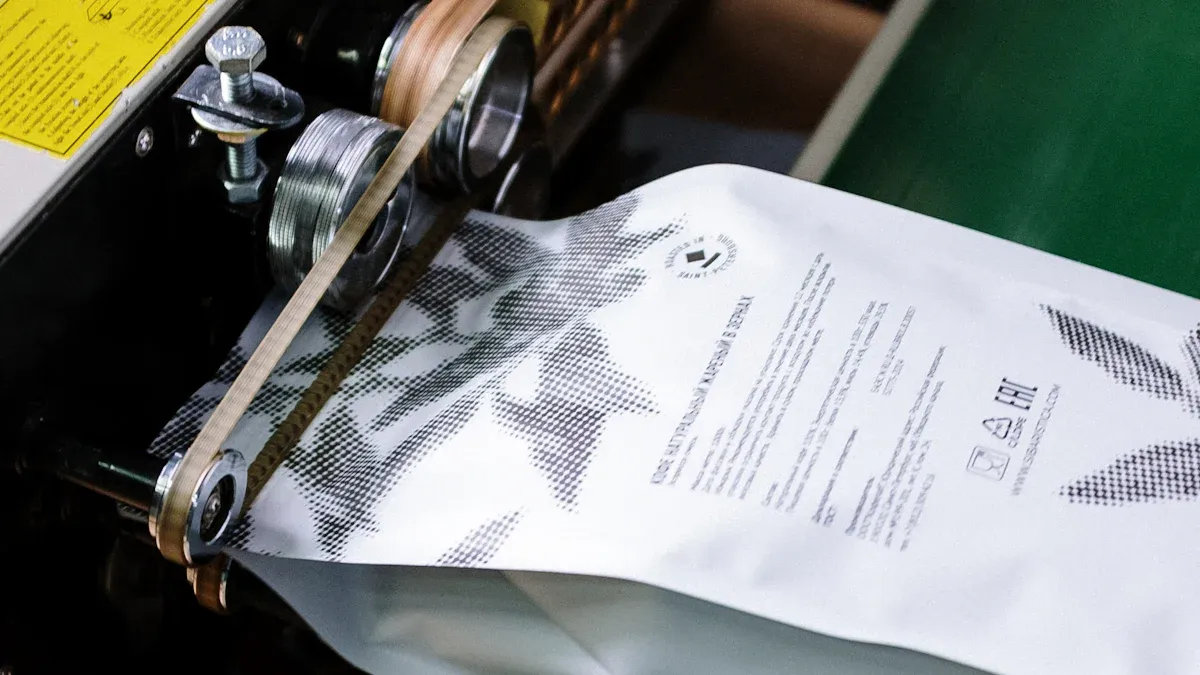

The production process of a valve bag making machine begins with material feeding. Operators load large rolls of flat material, such as kraft paper, polyethylene, or polypropylene, onto the unwinding system. The machine automatically unwinds these rolls and feeds the material into the production line. This roll-fed system supplies a continuous stream of material, which supports high-speed operation and reduces manual labor.

Valve bag making machines use automated feeding systems to maintain consistent tension and alignment. This precision prevents wrinkles and misalignment, which can affect the quality of the valve bag. The feeding system cuts the material to the correct length for each bag, ensuring uniformity throughout the production process. Automated feeding also minimizes downtime and waste, which increases overall efficiency.

Tip: Automated material feeding helps manufacturers meet high-volume demands while maintaining consistent bag quality.

After material feeding, the production process moves to tube forming. The machine shapes the flat material into a cylindrical tube, which forms the main body of the valve bag. The tuber machine performs this step by folding the edges of the material and sealing them together. This creates a strong, seamless tube that serves as the foundation for the bag.

The working principle behind tube forming relies on precise folding and sealing. The machine uses heat or adhesive to bond the edges, depending on the material type. This step is crucial for the structural integrity of the valve bag. The integration of tuber and bottomer machines in a single production line streamlines the process and reduces labor costs. Continuous tube forming allows the valve bag making machine to operate efficiently and produce large quantities of bags without interruption.

Once the tube forms, the production process continues with cutting and shaping. The machine uses a cutting system equipped with rotary knives to cut the tube into individual bags of the desired length. This step requires high precision to ensure each valve bag meets strict size and shape specifications.

The cutting and shaping process involves several key components:

| Component | Role in Precision During Cutting and Shaping |

|---|---|

| Cutting System | Rotary knives cut bags to exact length and shape, ensuring uniformity and correct sizing. |

| Unwinding System | Maintains tension and guides edges to prevent distortion, supporting precise cutting and shaping. |

| Perforation System | Adds easy-tear perforations accurately, enhancing functional precision in bag design. |

| Printing System | Applies designs and information accurately, complementing the precision in cutting and shaping. |

The working principle of the cutting system ensures that every valve bag has clean edges and consistent dimensions. The machine may also add perforations or print information on the bag during this stage. These features improve the usability and appearance of the final product. The production process at this stage sets the foundation for the next steps, such as valve insertion and sealing.

Note: Precision in cutting and shaping is essential for the performance and appearance of the valve bag, especially when used with a valve bag filling machine.

Valve insertion stands as a critical step in the valve bag making process. Modern machines use advanced technology to ensure each valve is placed accurately and securely. The valve acts as a one-way air release system, allowing for efficient filling and automatic sealing after the bag is filled. Depending on the bag design, the valve can be an inner or outer port.

Automated valve insertion relies on several key technologies:

Precise tube forming, cutting, and gluing mechanisms work together to prepare the bag for valve placement.

Advanced control systems with digital controls and sensors ensure each valve is positioned correctly and glue is applied consistently.

AI visual inspection systems monitor the process, improving production efficiency and product quality.

Floating rollers control the tension of film materials, which helps maintain stability and high standards during production.

Integration with other packaging equipment, such as a valve bag filling machine, supports scalability and smooth operation.

These technologies enable high-speed, precise, and consistent valve insertion. The result is a bag that can be filled quickly and sealed tightly, reducing the risk of spillage or contamination. Automated systems also minimize manual labor and help maintain uniform quality across large production runs.

Folding and sealing give the valve bag its final shape and strength. This stage ensures the bag can hold its contents securely during transport and storage. Several methods exist for folding and sealing, each chosen based on the bag type and intended use.

Common folding and sealing techniques include:

The Tuck-In Sleeve method uses a simple manual fold, where a flap is tucked into the opening after filling. This creates a tight closure that prevents leakage and spillage.

The design leverages internal product pressure to automatically close the valve, keeping the contents secure.

Tuber machines form the bag tube with consistent size and durability, providing a strong foundation.

Bottomer machines perform precise folding, gluing, and sealing of the bag bottom, which ensures strength and load capacity.

Valve making machines create the valve for automatic filling lines, securing closure and preventing leakage.

Side gluing combined with high-precision tube forming machines creates uniform, tight seals around the bag tube.

Servo-driven systems enhance accuracy and reduce material waste, which is important for high-volume production.

Bottom pasting machines fold and glue the bag bottom while forming the valve section at the same time.

Heat sealing technology plays a major role in this process. Machines use heat sealing technology to bond the bag layers together, creating a strong and durable seal. This method does not require glue, which makes the process cleaner and more efficient. Heat sealing technology also supports the production of recyclable and biodegradable bags, helping companies meet sustainability goals. The use of heat sealing technology ensures that each bag is sturdy, leak-proof, and ready for use with a valve bag filling machine.

Quality control is essential throughout the valve bag making process. Modern machines use intelligent detection systems to monitor every stage in real time. These systems help identify and correct issues before they affect the final product.

The machine features an intelligent detection device that monitors for abnormalities and triggers alarms to ensure product quality and safety. Operators can use recipe-based production data sets for different bag sizes and types, which allows for precise parameter management and optimized quality control. The PLC control system manages bag dimensions, sealing temperature, and speed, reducing human error. A touch screen interface provides real-time production data and fault alerts, making it easier for operators to spot and fix problems quickly.

| Feature/Function | Description |

|---|---|

| Visual Inspection Technology | Uses 4K cameras and infrared detection to achieve a leakage rate below 0.15%, reducing scrap rates. |

| Real-time Monitoring & Alarm | Photoelectric detection enables automatic fault alarms and machine shutdown to prevent defective bags. |

| IoT Support | Remote monitoring allows real-time viewing of equipment status and production data. |

| Human-Machine Interface | Touch screen and buttons make parameter setting and operation convenient. |

| Safety Protections | Protective covers and emergency shutdown features ensure operator safety. |

| Data Management | Servo conveying system supports accurate counting, stacking, and adjustable conveying distance. |

Machines use thermal imaging and AI algorithms to inspect every bag seal immediately after sealing. These systems detect defects such as improper seals, product residue, crushed bags, or bad sealer adjustments. They provide real-time alerts and can stop production or reject defective bags through PLC integration. Operators can review production data for performance analysis and process optimization. This approach enables 100% inspection, reducing manual checks and minimizing bag rejects. The system also supports plug-and-play integration with existing packaging machines, offering flexible deployment.

Quality control and quality inspection ensure that every valve bag meets strict standards for strength, sealing, and appearance. By using advanced heat sealing technology and intelligent monitoring, manufacturers can deliver reliable products that perform well in demanding applications.

A precision cutting valve bag-making machine stands out for its advanced features and accuracy. Manufacturers rely on this type of cutting valve bag-making machine to deliver consistent results for demanding industries. The machine uses high precision cutting to create bags with exact dimensions and clean edges. Operators benefit from touch screens, automated tension control, and high-speed servo motors, which all contribute to superior precision and efficiency.

The cutting valve bag-making machine supports multiple layers, such as 2-4 layers of paper plus a PE film, making it suitable for heavy-duty applications.

Programmable control systems allow quick adjustments for different bag sizes and shapes, increasing flexibility.

The machine offers stepped cutting, flake valve options, and external reinforcement printing, which are not available in standard models.

User-friendly control panels and advanced control systems improve operational efficiency.

Fully automated models reduce manual intervention and boost production speed while maintaining quality.

| Feature | Description |

|---|---|

| Bag layers | 2-4 layers of paper + 1 PE film (total 5 layers) |

| Standard cutting | Flake valve, stepped cutting |

| Optional cutting | Straight cutter |

| Printing | 4-color standard; 2-color for external reinforcement (optional) |

| External reinforcement | Available as an option |

| Tube length | 500-1100 mm |

| Edge width | 370-620 mm (A-shaped) |

| Max speed (tubes/min) | 170 (normal), 120-140 with external reinforcement |

| Max paper reel diameter | 1300 mm |

| Power consumption | 35 KW |

| Machine size | 28.72 m x 2.38 m x 2.875 m |

This cutting valve bag-making machine is ideal for kraft paper valve bags used in cement, chemical, and sack bag production. The advanced features ensure every bag meets strict industry standards.

An economical cutting valve bag-making machine provides reliable performance at a lower cost. Many businesses choose this type of cutting valve bag-making machine to balance quality and budget. The machine uses simplified mechanisms to reduce expenses while still delivering consistent results. Operators can quickly set up the machine for different bag sizes, making it practical for small and medium-sized production runs.

The economical cutting valve bag-making machine uses fewer advanced components, which lowers maintenance costs.

It supports basic cutting and sealing functions, making it suitable for standard packaging needs.

The machine offers steady output and dependable quality, even with less automation technology.

Operators can easily learn to use the machine, thanks to straightforward controls.

The economical cutting valve bag-making machine helps companies meet production targets without overspending.

This cutting valve bag-making machine is a smart choice for businesses that need to manage costs while maintaining good product quality.

Automation technology plays a key role in modern cutting valve bag-making machine design. Automated systems help manufacturers increase productivity and reduce labor costs. The cutting valve bag-making machine uses automation technology to handle feeding, folding, gluing, and sealing with minimal human input. Operators benefit from PLC-controlled operation and touchscreen interfaces, which make the process simple and efficient.

Automation technology reduces the need for skilled labor, allowing one operator and two assistants to manage the entire line.

Touchscreen controls shorten training time to just one day.

The cutting valve bag-making machine can produce up to 130 bags per minute, running 24 hours a day.

Real-time monitoring and error detection sensors help maintain consistent quality and minimize downtime.

Quick format switching supports flexible production, letting operators change bag designs easily.

Automation technology ensures stable output and reduces material waste.

| Aspect | Impact of Automation |

|---|---|

| Labor Costs | Automation reduces manual intervention, lowering the number of operators needed. |

| Production Throughput | High-speed, continuous operation enables increased output compared to manual methods. |

| Cost Efficiency | Lower production cost per unit due to streamlined processes and reduced labor requirements. |

Automation technology in the cutting valve bag-making machine helps companies achieve higher productivity, better quality, and lower costs. This technology supports both precision and efficiency, making it essential for modern packaging operations.

Durability stands as a core feature of modern valve bag making machines. Manufacturers design these machines to withstand continuous operation in demanding industrial environments. High-quality steel frames and reinforced components help the machines resist wear and tear. Operators can rely on these machines for long-term use without frequent breakdowns.

Engineers select materials that offer resistance to corrosion and mechanical stress. This choice extends the lifespan of critical parts such as cutting blades, rollers, and sealing units. Many machines include protective covers and dust-proof enclosures. These features shield sensitive components from debris and moisture, which can cause damage over time.

Routine maintenance becomes easier with modular designs. Technicians can replace worn parts quickly, reducing downtime. Some machines feature self-lubricating systems that keep moving parts in good condition. This technology further enhances durability and supports consistent production efficiency.

Manufacturers also test machines under real-world conditions before shipping. These tests ensure that each unit meets strict standards for strength and reliability. As a result, businesses experience fewer interruptions and maintain steady output. Durable machines help companies achieve high production efficiency and reduce long-term costs.

Tip: Investing in a durable valve bag making machine reduces repair expenses and supports uninterrupted production.

Modern valve bag making machines deliver impressive speed and efficiency. These qualities play a vital role in meeting high-volume packaging demands and improving production efficiency.

Machines such as the Tecon servo tuber machine ZT 8762 S operate at speeds of 80-120 bags per minute.

Multiple servo motors drive the system, enabling precise and efficient performance.

Rapid production allows companies to handle large orders in less time, which leads to increased productivity.

High-speed operation reduces labor costs and minimizes material waste.

Seamless integration with automated packaging lines streamlines the entire process.

The combination of speed and automation results in cost savings, consistent bag quality, and improved manufacturing production efficiency.

Operators benefit from real-time monitoring systems that track output and detect errors quickly. These systems help maintain high production efficiency by preventing defects and reducing downtime. Companies can adjust machine settings to match different bag sizes or materials, which adds flexibility to the production line.

Production efficiency improves not only through speed but also through smart design. Automated feeding, cutting, and sealing processes ensure that each step runs smoothly. This approach supports a steady workflow and helps businesses meet tight deadlines.

Note: High-speed machines with advanced automation set new standards for production efficiency in the packaging industry.

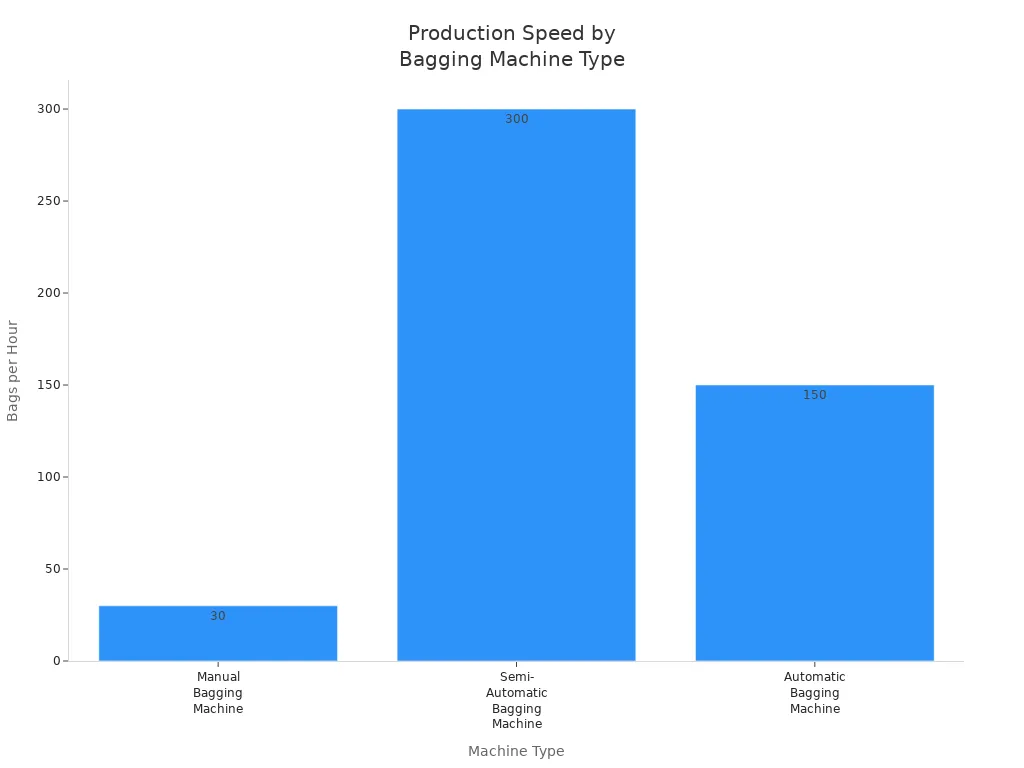

Manual machines represent the most basic types of valve bag filling machines. Operators perform every step by hand. They position each pp square bottom valve bag, fill it with product, and seal it manually. This method gives workers full control over the process. Manual machines work well for small businesses or operations with low production needs.

Manual machines offer high flexibility. Workers can quickly switch between different bag sizes or products. This makes manual machines suitable for custom orders or frequent changes. However, manual machines require several workers to keep up with demand. Production speed remains low, usually between 20 and 40 bags per hour. Labor costs can rise because of the need for more staff.

Tip: Manual machines provide a cost-effective solution for startups or companies with limited budgets. They also allow easy adaptation to new products or packaging styles.

Semi-automatic machines combine manual and automated steps. Operators place each pp square bottom valve bag onto the outlet. They start the filling process by turning on a feed switch. The machine fills the bag to a preset weight. When the bag reaches the correct weight, the operator moves it into the sealing track. The machine then seals the bag automatically.

Semi-automatic types of valve bag filling machines increase production speed compared to manual models. A typical semi-automatic line can fill 300 to 350 bags per hour with high accuracy. These machines often require three to four workers. They are common in construction for packing cement, putty, and similar materials. Accessories such as dust removal systems, bag vibrating, sewing machines, heat sealers, weight detection, metal detection, rejection systems, and labeling improve efficiency and product quality.

Semi-automatic machines offer a balance between cost and output. They provide better consistency than manual machines. Operators still need to handle some steps, but automation reduces errors and speeds up the process.

Automatic machines handle every step of the process. These types of valve bag filling machines place, fill, and seal each pp square bottom valve bag without manual intervention. Operators only need to monitor the system and supply materials. Automatic valve bag making machines use advanced sensors and control systems to ensure accuracy and speed.

Production speed for automatic machines ranges from 100 to over 200 bags per hour. Some models can run with just one or two workers. Automatic machines deliver excellent consistency and reduce labor costs. They suit large-scale operations that need high output and strict quality control.

The table below compares the main features of manual, semi-automatic, and automatic machines:

| Feature | Manual Bagging Machine | Semi-Automatic Bagging Machine | Automatic Bagging Machine |

|---|---|---|---|

| Operation | Fully manual: bag positioning, filling, sealing by hand | Manual bag loading; automatic filling and sealing | Fully automatic: bag placement, filling, sealing |

| Production Speed | 20-40 bags/hour | Around 250-350 bags/hour | 100-200+ bags/hour |

| Labor Requirement | High (multiple workers needed) | Moderate (3-4 workers typically) | Low (1-2 workers) |

| Flexibility | High (easy to adapt to product changes) | Moderate | Moderate |

| Cost | Low initial investment, higher labor costs | Moderate initial cost, balanced labor costs | High initial investment, lower labor costs |

| Consistency | Variable quality | Improved consistency | Excellent consistency |

Automatic machines often work with pp square bottom valve bag designs for industries such as chemicals, food, and construction. These machines help companies meet high-volume demands and maintain strict standards. Many businesses choose automatic machines to reduce errors and improve efficiency. The types of valve bag filling machines available today allow companies to select the best option for their needs.

Manufacturers use different materials to produce valve bags, each with unique properties. The most common materials include paper (multiwall kraft), polyethylene (PE), and polypropylene (PP). These materials affect the performance, durability, and application of the bags.

The table below compares the advantages and disadvantages of each material:

| Material | Advantages | Disadvantages |

|---|---|---|

| Paper (Multiwall Kraft) | Traditional, widely used for dry bulk goods | Susceptible to moisture and environmental damage; reduced durability and strength in wet/harsh conditions; less reliable sealing (glue/sewing); lower thermal stability |

| PE (Polyethylene) Films | Lightweight, flexible, cost-effective for light-duty packaging | Lacks structural integrity and durability; prone to tearing, puncturing, deformation under extreme temperatures, UV exposure, or rough handling; limited resistance to environmental conditions |

| PP (Polypropylene) Valve Bags | Superior tensile strength and durability; moisture and dust resistant; maintains shape under challenging conditions; efficient airtight valve system for dust-free filling and sealing; better sealing reliability and operational efficiency; thermal stability; versatile and robust for industrial use | Requires precise quality control; occasional customization needed; some production challenges |

PP square bottom valve bag stands out as the preferred choice for many industries. This bag offers high strength and resists moisture, making it suitable for harsh environments. Companies often select the pp square bottom valve bag for packaging cement, chemicals, and food products. The airtight valve system in the pp square bottom valve bag ensures dust-free filling and reliable sealing. This feature helps protect the contents and keeps the workplace clean.

PE valve bags work well for light-duty packaging. They provide flexibility and cost savings. However, they do not match the durability of the pp square bottom valve bag. Paper valve bags remain popular for dry goods, but they struggle in wet or rough conditions. The pp square bottom valve bag maintains its shape and strength even when stacked or transported over long distances.

Seamless square bottom bags made from PP offer extra benefits. These bags have no weak points at the seams, which increases their durability. Seamless square bottom bags also provide a smooth surface for printing, making branding easier. Many companies choose seamless square bottom bags to improve product appearance and shelf appeal.

Note: The choice of material affects not only the strength and durability of the bag but also its suitability for specific products and environments.

Block bottom valve bags have a unique structure that sets them apart from other packaging options. These bags feature a flat, stable base and wide side gussets. This design provides several benefits for industrial packaging:

The flat base prevents tipping and allows the bag to stand upright, which improves shelf appeal and safety.

Wide side gussets add strength and stability, making the bag more resilient during handling and transport.

The box-like shape of the block bottom valve bag increases the filling volume, allowing companies to pack more product in each bag.

The flat surfaces on all sides create ample space for branding and product information.

Block bottom valve bags stack easily and securely, which helps with storage and transportation.

High-quality materials and reinforced gussets protect the contents from damage, moisture, and contamination.

The structure resists dropping, pressing, puncturing, and bending, keeping products safe during every stage of the supply chain.

Many block bottom valve bags use a star micro-perforation system. This feature lets air escape without letting product spill out, which is important for powders like cement.

Laminated or coated layers improve resistance to water and humidity, making the bags suitable for outdoor storage.

Welded ends avoid the use of toxic glue, supporting environmental goals and making the bags fully recyclable.

These bags work well with palletizing and truck loading equipment, streamlining logistics.

The pp square bottom valve bag often uses the block bottom design. This combination creates seamless square bottom bags that offer both strength and efficiency. Companies in construction, agriculture, and chemicals rely on the pp square bottom valve bag for its stability and protective features. The seamless square bottom bags also help reduce waste and improve operational efficiency.

Tip: Block bottom valve bags provide a reliable and attractive solution for industries that need strong, stable, and easy-to-handle packaging.

The agriculture industry relies heavily on the cutting valve bag-making machine for packaging dry, flowable products. Farmers and producers use valve bags to store and transport grains, fertilizers, and animal feed. These bags feature self-sealing valves that prevent leaks and spillage during filling and shipping. The construction of valve bags, often from woven polypropylene or laminated paper, provides strength and moisture resistance. This design protects the contents from contamination and ensures consistent product quantity.

Valve bags have served agriculture since the 1920s. They are ideal for powders and granules, such as cleaned shelled corn and wildlife feed. The cutting valve bag-making machine enables fast, high-volume production of these bags. Producers benefit from water-resistant packaging that keeps products safe in storage and transit. The lightweight nature of valve bags allows more bags per pallet, improving warehousing and shipping efficiency.

Key reasons agriculture prefers valve bags:

Fast filling with high-speed equipment

Self-sealing valves for leak prevention

Strong, moisture-resistant materials

Efficient stacking and handling

Note: Valve bags help minimize product loss and maintain quality, making them a top choice for agricultural packaging.

Chemical manufacturers require strict safety and containment for their products. The cutting valve bag-making machine produces valve bags that meet these needs. Chemical products, such as powders and granules, often pose hazards if spilled or exposed to moisture. Valve bags offer airtight seals that prevent leaks and spills, protecting both workers and the environment.

Manufacturers may add gaskets or special seals to enhance protection. These bags must also be compatible with hazardous materials and comply with industry regulations. The valve design allows precise control over filling and discharge, reducing exposure risks. Integration with automated equipment, like hoppers and conveyors, limits manual handling and contamination.

Features important for chemical applications:

Airtight sealing to contain hazardous materials

Additional gaskets for leak prevention

Compatibility with safety standards and regulations

Valves for controlled discharge and minimal residue

Valve bags help chemical companies reduce waste, prevent pollution, and maintain product quality during storage and transport.

Food producers use the cutting valve bag-making machine to create packaging that meets strict hygiene and safety standards. The food industry demands materials that comply with regulations such as CFR Title 21 and EU food contact laws. Valve bags for food applications often use food-grade materials, like specific plastics or coated papers, that resist corrosion and withstand processing conditions.

Designers focus on hygienic construction, including smooth surfaces and rounded corners, to prevent microbial contamination. The valve system must avoid damaging food particles and allow for easy cleaning. These features help maintain product integrity and safety from the packaging line to the consumer.

Key requirements for food packaging:

Use of approved, food-safe materials

Hygienic design for easy cleaning and inspection

Protection against contamination and spoilage

Compliance with global food safety standards

Tip: The applications of cutting valve bag-making machines in the food sector ensure safe, efficient, and reliable packaging for products like flour, sugar, and processed grains.

The construction industry depends on valve bag making machines for packaging materials like cement, mortar, plaster, and dry mixes. These products require strong, reliable packaging to prevent spillage and contamination. Valve bags offer a secure solution because they seal automatically after filling. This feature keeps dust and fine powders inside the bag, which helps maintain a clean work environment and reduces product loss.

Valve bags for construction materials must meet strict standards. Manufacturers use robust materials such as multi-ply paper or woven polypropylene. These materials withstand the weight and abrasive nature of cement powder. The valve mechanism allows for fast, clean filling and controlled discharge. This design minimizes dust and spillage, which is important for worker safety and environmental protection.

Key considerations for valve bags in construction include:

Proper sealing and stitching for bag strength and durability.

Consistent bag dimensions for efficient stacking and storage.

Moisture-resistant coatings or liners to protect contents during transport.

Static eliminators and clean environments to control dust and static electricity.

Compatibility with filling machines to reduce spillage and wastage.

Compliance with safety, labeling, and environmental regulations.

Use of recyclable or eco-friendly materials to support sustainability goals.

| Consideration | Explanation |

|---|---|

| Strength and Durability | Bags resist tearing and puncturing, keeping cement safe. |

| Valve Mechanism | Enables rapid, dust-free filling and automatic sealing. |

| Moisture Resistance | Coatings or liners protect against water damage. |

| Stackability | Uniform size allows secure stacking on pallets. |

| Cost-Effectiveness | Mass production and economical materials lower packaging costs. |

| Environmental Sustainability | Many bags are recyclable, reducing environmental impact. |

| Quality Control | Regular checks ensure proper sealing and consistent dimensions. |

| Transportation and Storage | Proper palletizing and trained workers prevent damage during handling and shipping. |

Construction companies choose valve bags because they improve efficiency and safety. The bags work well with automated filling and palletizing equipment. This integration speeds up production and reduces labor costs. Valve bags also help companies meet environmental and regulatory standards, making them a preferred choice for modern construction sites.

Valve bag making machines serve many other industries beyond agriculture, chemicals, food, and construction. These machines package products in sectors such as mining, pharmaceuticals, plastics, and consumer goods. Each industry values the unique benefits of valve bags, including secure sealing, efficient filling, and protection from moisture and contamination.

In the mining industry, companies use valve bags to package minerals, ores, and fine powders. The bags prevent dust release and keep materials safe during transport. Pharmaceutical manufacturers rely on valve bags for bulk powders and granules. The self-sealing valve maintains product purity and meets strict hygiene standards.

Plastics and resin producers use valve bags to package pellets and granules. The bags’ strength and dust control features protect the product and the environment. Consumer goods companies use valve bags for items like detergents, pet food, and lawn care products. The bags’ customizable size and branding options help companies stand out on store shelves.

The wide range of applications for valve bag making machines shows their versatility. Industries choose valve bags for their ability to improve packaging efficiency, reduce waste, and protect valuable products.

Selecting the right capacity for a valve bag making machine ensures efficient operation and meets production goals. Companies must consider several factors before making a decision. The table below highlights key points to evaluate:

| Factor | Explanation |

|---|---|

| Automation Level | Higher automation increases production speed and precision, but also raises costs. |

| Machine Design and Quality | Well-designed machines support faster speeds and better durability, which boosts overall capacity. |

| Maintenance and Technical Support | Regular maintenance and easy access to support reduce downtime, keeping production steady. |

| Bag Size and Capacity | Machines differ in the size and weight of bags they can produce, affecting output per shift. |

| Type of Valve | The valve type (self-sealing, open-mouth, pinch-bottom) must match the product and filling process. |

| Material Thickness and Composition | Machines must handle specific materials and thicknesses for reliable operation. |

| Speed and Efficiency | Faster machines increase output, but efficiency also depends on waste reduction and quality control. |

| Cost and Budget | The machine’s price and ongoing expenses must fit the company’s budget while meeting capacity needs. |

| Compatibility with Materials | Machines should process the chosen materials without frequent jams or defects. |

A company that produces large volumes of cement bags, for example, needs a machine with high speed and robust construction. Smaller operations may choose a lower-capacity model for flexibility and cost savings. Matching machine capacity to business needs prevents bottlenecks and supports high-quality production.

Machine quality plays a major role in the reliability and lifespan of valve bag making equipment. Manufacturers use durable materials like stainless steel and wear-resistant alloys to extend the life of their machines. A strong frame allows for continuous operation, even in demanding environments. Well-designed machines feature critical parts, such as glue applicators and rollers, that are easy to clean and replace. This design reduces downtime and keeps production lines running smoothly.

Reliable after-sales service also matters. Companies benefit from fast troubleshooting, operator training, and a steady supply of spare parts. These services help minimize downtime and extend equipment lifespan. Regular inspection and timely replacement of moving parts, such as belts and cutting blades, prevent unexpected breakdowns. Precise calibration and alignment ensure consistent bag quality and reduce wear on components.

Tip: Investing in a high-quality machine reduces maintenance needs and supports long-term reliability.

Every business has unique packaging requirements. Customization options allow companies to tailor valve bag making machines to their specific needs. Manufacturers can adjust machines for different bag sizes, materials, and valve types. Some machines offer modular designs, making it easy to add or remove features as production demands change.

Customizable machines can handle a wide range of products, from fine powders to coarse granules. This flexibility supports growth and helps companies respond to market changes. Custom printing and branding options also enhance product appearance and support marketing efforts.

A machine that adapts to different materials and bag designs gives companies a competitive edge. Customization ensures the machine fits current needs and can evolve with future demands.

Proper maintenance ensures that a valve bag making machine operates efficiently and lasts longer. Companies that invest in regular care for their machines see fewer breakdowns and higher productivity. Maintenance routines also help prevent costly repairs and unexpected downtime.

Operators should follow a scheduled preventive maintenance program. Qualified personnel must perform these checks to keep the machine in top condition. Regular lubrication of moving parts prevents wear and tear. Lubrication reduces friction, which helps the machine run smoothly and extends the life of critical components.

Frequent inspections play a key role in maintenance. Technicians should look for damaged parts or alignment issues. Early detection of problems allows for quick repairs before they become serious. Keeping a spare parts kit on hand helps avoid production delays when a component needs replacement.

Tip: A well-stocked spare parts kit can save valuable time during unexpected repairs.

Operators need proper training to handle the machine safely and efficiently. Training programs should cover daily checks, cleaning routines, and emergency stop procedures. Clear operating procedures help staff avoid mistakes that could damage the equipment. Companies that invest in staff training see fewer accidents and better machine performance.

Routine calibration of sensors and adjustment of machine settings ensure accurate operation. Sensors that measure bag length, sealing temperature, and filling weight must stay within set limits. Regular calibration keeps the machine producing high-quality bags and reduces waste.

A maintenance checklist can help teams stay organized. Here are some important tasks to include:

Lubricate all moving parts as recommended by the manufacturer.

Inspect belts, rollers, and cutting blades for signs of wear.

Check alignment of feeding and sealing units.

Clean dust and debris from sensitive components.

Calibrate sensors and adjust machine settings regularly.

Test emergency stop mechanisms to ensure safety.

Replace worn or damaged parts promptly.

Review quality control procedures after each maintenance session.

Note: Consistent maintenance not only extends the life of the machine but also supports product quality and workplace safety.

By following these best practices, companies can maximize the performance of their valve bag making machines. Regular care reduces downtime, improves efficiency, and helps maintain a safe working environment.

Manufacturers who want to achieve the best results with valve bag making machines should follow proven best practices. They start by setting clear production goals and monitoring progress daily. Operators check machine settings before each shift. They use checklists to confirm that all parts work correctly. Teams keep the work area clean to prevent dust and debris from affecting the machine.

Many companies use standard operating procedures (SOPs) for every step. These SOPs help workers follow the same process each time. Managers review production data to spot trends or problems early. They encourage open communication so workers can report issues quickly. Teams also schedule regular audits to review safety and quality standards.

Tip: Consistent use of best practices leads to fewer errors and higher output.

Routine maintenance keeps valve bag making machines running smoothly. Operators should inspect moving parts, such as belts and rollers, for signs of wear. They replace worn parts before they cause breakdowns. Lubrication of gears and bearings reduces friction and extends the life of the machine.

A maintenance log helps track repairs and replacements. Teams use this log to plan future maintenance and avoid unexpected downtime. Cleaning the machine after each shift removes dust and prevents blockages. Technicians check sensors and control panels to ensure accurate operation. They also test emergency stop buttons for safety.

The table below lists common maintenance tasks and their benefits:

| Task | Benefit |

|---|---|

| Lubricate parts | Reduces wear and tear |

| Inspect belts | Prevents sudden breakdowns |

| Clean machine | Maintains product quality |

| Check sensors | Ensures accurate operation |

| Replace worn parts | Avoids costly repairs |

Note: Regular maintenance supports improved quality and extends equipment lifespan.

Well-trained staff play a key role in ensuring quality and efficiency. Companies provide training for new operators and refresher courses for experienced workers. Training covers machine operation, safety procedures, and troubleshooting. Instructors use hands-on practice and visual aids to help staff learn quickly.

Managers encourage teamwork and communication. They hold regular meetings to discuss challenges and share solutions. Staff learn how to spot early signs of machine problems. They also practice emergency procedures to stay prepared.

A strong training program builds confidence and reduces mistakes. Workers who understand the machine can solve problems faster and keep production on track.

Performance monitoring helps companies keep valve bag making machines running at their best. This process involves tracking machine activity, measuring output, and checking for problems. Operators and managers use performance data to make smart decisions and improve production.

Key Metrics to Track:

| Metric | What It Shows | Why It Matters |

|---|---|---|

| Output Rate | Number of bags produced per hour | Measures productivity |

| Downtime | Minutes or hours machine is not running | Identifies lost production time |

| Defect Rate | Percentage of bags with errors | Tracks quality issues |

| Material Waste | Amount of unused or scrapped material | Shows efficiency of operation |

| Energy Consumption | Power used during production | Helps control operating costs |

Operators check these metrics daily. They use digital displays or software dashboards to see real-time data. Many modern machines have sensors that collect information automatically. These sensors track speed, temperature, and pressure. If a value goes outside the normal range, the system sends an alert.

Tip: Early detection of problems helps prevent bigger breakdowns and saves money.

Companies often set performance targets for each shift. Teams review results at the end of the day. If output drops or defects rise, managers investigate the cause. They may adjust machine settings, replace worn parts, or retrain staff. Regular reviews help teams spot trends and fix issues before they get worse.

Performance monitoring also supports preventive maintenance. By tracking machine hours and wear, operators know when to schedule service. This approach reduces unexpected downtime and keeps production steady.

Steps for Effective Performance Monitoring:

Set clear goals for output, quality, and efficiency.

Use sensors and software to collect accurate data.

Review metrics daily and compare them to targets.

Respond quickly to alerts or unusual trends.

Keep records for long-term analysis and improvement.

Performance monitoring creates a cycle of continuous improvement. Teams learn from the data and make changes that boost quality and efficiency. Over time, this leads to lower costs, better products, and higher customer satisfaction.

Note: Consistent monitoring is the foundation of a reliable and efficient valve bag making operation.

Valve bag making machines play a key role in modern packaging. They help companies improve efficiency and product safety. Choosing the right machine for each application leads to better results and lower costs. Manufacturers who follow best practices see higher quality and fewer problems.

For those interested in learning more, explore manufacturer guides, industry webinars, or technical articles on valve bag technology. Staying informed helps businesses stay ahead in packaging innovation.

Most valve bag making machines last 8 to 12 years with regular maintenance. High-quality machines and proper care can extend this period. Operators should follow the manufacturer’s maintenance schedule to maximize machine life.

Yes, many modern machines offer adjustable settings for various bag sizes. Operators can change parameters using the control panel. This flexibility helps manufacturers meet different packaging needs without buying extra equipment.

Operators should perform basic checks daily and schedule thorough maintenance monthly. Regular cleaning, lubrication, and inspection of moving parts help prevent breakdowns. Following a maintenance log ensures no step gets missed.

Manufacturers design specific models for food packaging. These machines use food-grade materials and meet hygiene standards. Operators must keep the machine clean and follow safety guidelines to ensure food safety.

Staff need hands-on training on machine operation, safety procedures, and troubleshooting. Many companies provide manuals and video tutorials. Ongoing training helps staff stay updated on best practices.

Many machines can process both paper and plastic films. Operators select the correct settings for each material. Some models may require special parts or adjustments for optimal performance.

Automation reduces manual labor and speeds up production. Machines with automated feeding, cutting, and sealing produce more bags per hour. Real-time monitoring helps operators catch problems early, which keeps output high.