- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-25 Origin: Site

You face an important comparison when choosing between semi-automatic and fully automatic paper bag machines. Large manufacturers often select fully automatic machines because they deliver higher speeds, efficiency, and lower labor costs, which makes them better for high-volume needs. Small and medium businesses usually find semi-automatic machines more affordable and flexible. When you weigh initial investment, ongoing costs, and production requirements, your decision becomes clearer. Eco Friendly Paper Bag Making Machine: Cost - Benefit Analysis helps you see which option best fits your goals.

When you compare semi-automatic and fully automatic paper bag machines, you notice clear differences in both upfront and ongoing costs. The initial investment for a semi-automatic machine usually ranges from $20,000 to $60,000. In contrast, a fully automatic paper bag machine can cost between $50,000 and $500,000. This price gap reflects the advanced technology and automated operation found in fully automatic machines.

| Machine Type | Average Upfront Cost Range (USD) |

|---|---|

| Semi-Automatic Machine | $20,000 - $60,000 |

| Fully Automatic Machine | $50,000 - $500,000 |

You also need to consider ongoing costs. Semi-automatic machines require more manual labor, which increases labor costs over time. Fully automatic machines reduce labor costs because they need less human intervention, but they come with higher maintenance expenses. The automated operation in fully automatic machines means you spend less on labor but more on technical upkeep.

Industry research shows that semi-automatic machines strike a balance between efficiency and cost. They offer moderate throughput and manageable operational costs, making them a good choice for medium-sized packaging businesses. Fully automatic machines, on the other hand, suit large-scale packaging operations that need high-speed production and can handle higher initial and maintenance costs.

| Machine Type | Labor Costs | Maintenance Costs | Operational Characteristics |

|---|---|---|---|

| Fully Automatic | Lower labor costs | Higher maintenance | Minimal human intervention, higher upfront investment |

| Semi-Automatic | Moderate labor | Moderate maintenance | Combines manual bag positioning with automatic filling/sealing |

The main differences between semi-automatic and fully automatic paper bag machines come down to cost, labor, and production speed. Semi-automatic machines have a lower initial investment and simpler maintenance. They fit small to medium packaging businesses that want to automate some steps but still rely on manual work. Fully automatic machines require a much higher upfront cost but deliver faster production speeds and lower labor costs due to their advanced automated operation.

| Cost Aspect | Semi-Automatic Machines | Fully Automatic Machines |

|---|---|---|

| Initial Investment | Lower, suitable for small budgets | Higher, designed for large factories |

| Labor Costs | Higher, requires more manual operation | Lower, due to automation |

| Maintenance | Simpler and less costly | More complex and expensive |

| Production Speed | Moderate, fits small to medium output needs | High, suitable for mass production |

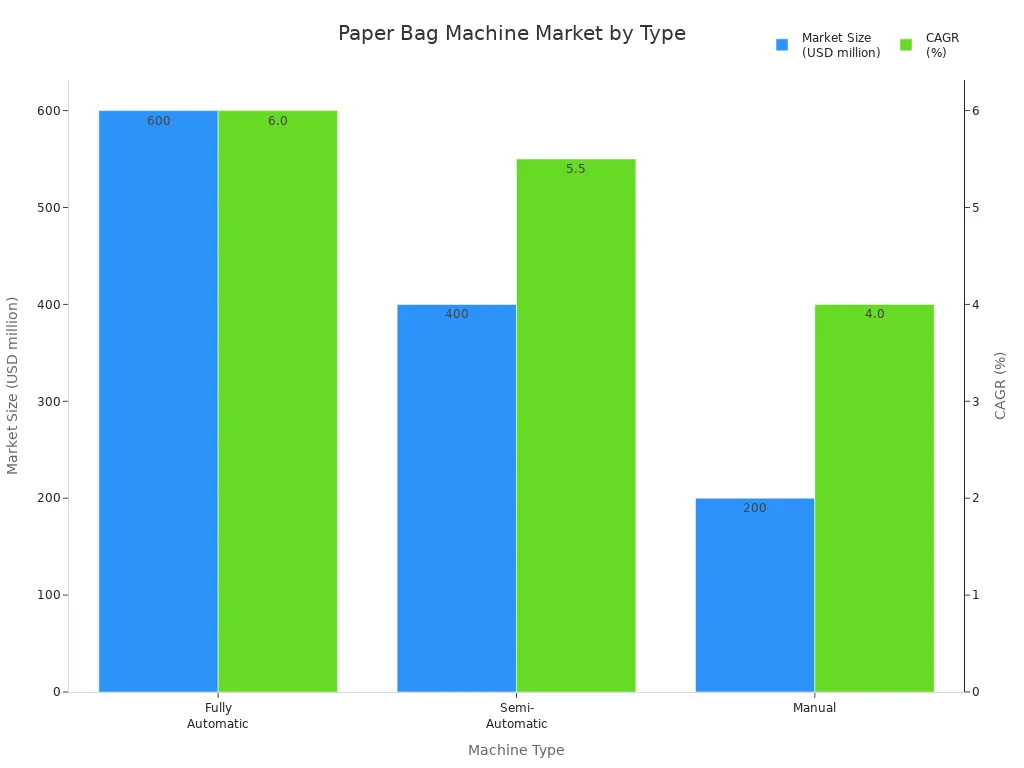

You see these trends in the global market as well. Fully automatic paper bag machines dominate large-scale packaging because they offer high efficiency and reduced labor costs. However, their high price keeps many small businesses from upgrading. In regions like sub-Saharan Africa, over 46% of small packaging companies delayed buying new machines in 2023 because of the high cost of fully automatic machines.

If you run a small or medium packaging business, semi-automatic machines let you balance automation and cost. You can improve productivity without the heavy financial burden of a fully automatic paper bag machine. For large manufacturers with higher budgets and production needs, fully automatic machines provide the speed and efficiency needed for mass production.

Tip: Always match your choice of paper bag machine to your business size, production goals, and available budget. The right balance between cost and automation can help your packaging business grow steadily.

When you consider buying paper bag machines, the initial cost stands out as a major factor. Semi-automatic machines usually have a lower purchase price. You can expect to pay between $20,000 and $60,000 for these machines. This range makes semi-automatic machines attractive for small and medium businesses that want to start producing paper bags without a huge investment. The lower initial cost allows you to allocate more funds to other parts of your business, such as marketing or raw materials.

Fully automatic machines come with a much higher initial cost. You might see prices from $50,000 up to $500,000. These machines use advanced technology and offer high-speed production. The higher price reflects the automation and efficiency you get. If you run a large factory or need to produce a high volume of paper bags, fully automatic machines can help you meet demand. However, you need to prepare for a significant upfront investment.

Note: Always compare the initial cost with your expected production needs. A lower purchase price may suit your current budget, but a higher investment in fully automatic machines could pay off if your business grows quickly.

After you buy paper bag machines, you face setup and training costs. These costs differ between semi-automatic and fully automatic machines. Semi-automatic machines have a simpler setup process. You do not need specialized installation or major changes to your workspace. Training for semi-automatic machines is easier because the operation is more user-friendly. Most workers can learn to use these machines quickly, which keeps training costs low.

Fully automatic machines require a more complex setup. You may need to modify your factory or bring in experts for installation. Training for fully automatic machines takes more time and money. The advanced features and automation mean your staff must learn new skills. Specialized training ensures your team can operate the machines safely and efficiently.

Here is a comparison of setup and training costs:

| Aspect | Semi-Automatic Paper Bag Machines | Fully Automatic Paper Bag Machines |

|---|---|---|

| Training Costs | Lower training costs due to user-friendly operation; requires less extensive training. | Higher training costs because of sophisticated operation and advanced technology requiring more specialized training. |

| Setup/Installation | Generally simpler setup; less specialized installation needed, leading to lower setup costs. | More complex setup requiring specialized installation and possibly infrastructure modifications, resulting in higher setup costs. |

| Operation Complexity | Balance of manual and mechanized processes; easier for small to medium businesses. | Minimal manual intervention; highly automated with features like auto-calibration and quality checks. |

| Cost Range | Approximately US$8,000 to US$12,000. | Approximately US$12,500 to US$21,500. |

| Long-term Labor Costs | Potentially lower due to ease of use and less training required. | Potentially higher initially but may be offset by efficiency gains over time. |

You should factor in both the initial cost and the setup and training expenses when choosing between semi-automatic machines and fully automatic machines. If you want to keep your upfront spending low and train your team quickly, semi-automatic machines offer a clear advantage. If you plan for long-term growth and need high-speed paper bag production, fully automatic machines may justify their higher initial cost through greater efficiency.

When you use semi-automatic paper bag machines, you need more manual intervention. Workers must load paper, position each bag, and sometimes handle the sealing process. This hands-on approach increases the number of people you need on the production floor. You must pay attention to labor hours because they make up a large part of your operating cost. If you run a small business, you might find this manageable. As your production grows, labor costs can rise quickly.

Fully automatic paper bag machines reduce the need for manual work. These machines handle most steps, from feeding paper to forming and sealing each bag. You can operate several machines with fewer workers. This automation leads to significant labor savings. Over time, you spend less on wages and training. If you want to lower your operating cost, fully automatic machines offer a clear advantage. You can focus your team on quality control and machine supervision instead of repetitive tasks.

Tip: If you want to scale your paper bag production without hiring more staff, consider investing in fully automatic machines.

Maintenance plays a big role in your total operating cost. Semi-automatic paper bag machines have a simpler design. You can maintain them more easily, and your team can often handle basic repairs. However, manual moving parts may wear out faster. You might need to replace parts more often, which can add up over five years.

Fully automatic paper bag machines require regular maintenance by skilled technicians. These machines use advanced monitoring systems that help prevent breakdowns. While the maintenance is more complex and expensive, you can avoid unexpected repair costs with proper scheduling. Many suppliers offer customized maintenance contracts for both types of machines. These contracts help you predict and manage your maintenance expenses.

| Machine Type | Maintenance Characteristics | 5-Year Maintenance Implications |

|---|---|---|

| Semi-Automatic | Easier to maintain; manual parts wear faster | Lower complexity, but more frequent part replacements |

| Fully Automatic | Needs skilled technicians; has monitoring systems | Higher complexity and cost, but fewer surprise repairs due to better scheduling |

| Both Types | Maintenance contracts available | Contracts help you plan and control maintenance costs |

Energy use affects your operating cost every month. Semi-automatic paper bag machines use less power because they run fewer automated systems. If you want to keep your energy bills low, these machines can help. Fully automatic paper bag machines use more electricity. Their motors, sensors, and control systems run all day to keep up with high-speed production. You pay more for energy, but you get faster output and better efficiency.

To manage your operational costs, always check the energy rating of your machines. Some modern paper bag machines come with energy-saving features. These features can lower your operating cost and help your business stay competitive.

Note: Tracking your energy use helps you spot ways to save money and reduce waste in your paper bag production.

When you compare semi-automatic and fully automatic paper bag machines, you see a big difference in production output. Semi-automatic machines can produce between 50 and 200 bags per minute. This output depends on the skill of your operators and the level of manual work involved. Fully automatic machines can reach hundreds or even up to 1,000 bags per minute. These machines run with continuous, high-speed production and need very little human intervention.

| Machine Type | Production Output (bags/min) | Operational Characteristics | Suitable For |

|---|---|---|---|

| Semi-automatic | 50 to 200 | Requires manual operation; output depends on operator skill | Small businesses, low-volume orders |

| Fully automatic | Hundreds up to 1000 | Continuous, fully automated operation; high-speed production | Large-scale production |

If you want to boost your paper bag production and meet large orders, fully automatic machines give you the production capacity you need. This higher output leads to greater productivity and helps you serve more customers in less time.

Efficiency plays a key role in your long-term savings and overall return on investment. Fully automatic machines use advanced automation, computerized controls, and real-time monitoring. These features increase production efficiency and keep product quality consistent. You also see less downtime and waste, which means you get more bags with fewer resources.

Here are some important efficiency metrics:

| Metric | Description / Values |

|---|---|

| Production Capacity | Ranges from 150 to 250 bags per hour depending on model |

| Energy Efficiency | Between 85% and 92% for various machine models |

| Downtime Reduction | Operator training can reduce downtime by up to 25% |

| Performance Monitoring | Real-time data analytics can boost efficiency by ~15% |

Fully automatic machines often outperform semi-automatic ones in these areas. You get higher production efficiency, better energy use, and improved product quality. Automation and smart technology help you maintain high-speed production and reduce mistakes. If you want to maximize productivity and quality, fully automatic machines offer a clear advantage.

Tip: Real-time monitoring and operator training can help you reduce downtime and improve efficiency, no matter which machine you choose.

The lifespan of your paper bag machine affects your long-term ROI. Most high-quality machines last between 10 and 20 years, or about 20,000 to 40,000 operational hours, if you maintain them well. Some manufacturers claim their fully automatic machines can last up to 30 years. Industry data shows that the average lifespan for bag-making machines is about 10 to 15 years, but this can vary based on how often you use the machine and how well you care for it.

You should look at both the upfront cost and the long-term savings from lower labor and higher productivity. Semi-automatic machines cost less at first, but you spend more on labor over time. Fully automatic machines require a bigger investment, but you save on labor and get higher production efficiency. For small businesses, semi-automatic machines may give you a faster return on investment because of the lower price. For large-scale paper bag production, fully automatic machines deliver better long-term savings and higher productivity.

Note: Regular maintenance and proper training help you extend the lifespan and maintain the quality of your machine, which protects your investment and ensures steady product quality.

When you run a small business, you need to watch your spending closely. The initial investment often becomes the biggest hurdle. You want a machine that fits your budget and helps you grow. Many small businesses choose between semi-automatic and fully automatic machines based on cost and efficiency.

Here is a quick comparison:

| Machine Type | Approximate Cost (Rs.) | Operational Consideration |

|---|---|---|

| Fully Automatic | 15 Lakh | More time-efficient, lower upfront cost |

| Semi-Automatic | 30 Lakh | More time-consuming, higher upfront cost |

| Manual | 55 Lakh | Most time-consuming, highest upfront cost |

You may notice that fully automatic machines can sometimes have a lower upfront cost than semi-automatic models. They also save you time and labor. However, you should always check the reliability of the manufacturer and the after-sales service. These factors help you avoid extra costs later.

Tip: If you want to maximize efficiency and keep costs low, consider a fully automatic machine from a trusted supplier.

Medium enterprises often need to balance production volume with budget limits. You want a machine that can handle more orders but does not break the bank. Machines with a capacity of 100-200 bags per minute usually fit this need. They offer a good mix of speed and affordability.

| Machine Type | Production Capacity (bags/min) | Suitable Enterprise Size | Budget Consideration | Key Features and Innovations |

|---|---|---|---|---|

| Semi-automatic | Up to 100 | Small and Medium | Cost-effective, lower capital | User-friendly, versatile, suitable for limited budgets |

| Medium-capacity | 100-200 | Medium | Balances efficiency and cost | Attractive for medium enterprises needing higher volume |

| Automatic | Above 200 | Large | Higher budget, high production need | IoT and AI integration, remote monitoring, high precision |

You may want to invest in a medium-capacity machine if you expect your business to grow. These machines help you increase output without a huge jump in cost. Some automatic machines now include smart features like IoT and AI, which can boost efficiency and reduce waste.

Note: Choose a machine that matches your current needs but can also support future growth.

Large manufacturers focus on high production and efficiency. You need machines that can run all day and produce thousands of bags quickly. Fully automatic machines work best for this scale. They offer advanced features, high speed, and lower labor costs over time.

Fully automatic machines lead the market for large manufacturers because they deliver the best results for high-volume production. These machines use advanced automation and can include features like hydraulic headboxes for consistent quality. While the initial investment is higher, the long-term savings and output make them the most cost-effective choice for large-scale operations.

If you run a large factory, fully automatic machines will help you meet demand and stay competitive.

You play a key role in reducing environmental harm when you choose an eco friendly paper bag making machine: cost - benefit analysis shows that these machines support sustainability at every step. These machines use recycled or FSC-certified paper, which helps protect forests and reduces waste. You also see less pollution because the machines use clean production methods. They often run on energy-efficient systems, sometimes powered by renewable energy. This means you use less electricity and lower your carbon footprint.

Eco friendly paper bag making machines also help you minimize waste. They use optimized cutting patterns and recycle offcuts, so you throw away less material. Water and emissions drop because the machines use advanced technology to clean up the production process. You meet consumer demand for sustainable packaging and help your business stand out as a responsible brand.

Note: When you invest in eco friendly paper bag making machine: cost - benefit analysis, you support both your business and the planet.

You may notice that the initial investment for an eco friendly paper bag making machine: cost - benefit analysis is higher than for traditional models. Prices usually range from $75,000 to $200,000 for new or refurbished units. You can lower your upfront costs by leasing equipment or buying used machines. You also need to budget for workspace setup, permits, recycled paper inventory, inks, adhesives, and staff salaries.

Here is a breakdown of typical startup costs:

| Expense Category | Cost Range (USD) |

|---|---|

| Machinery (new/refurb) | $75,000 - $200,000 |

| Workspace Setup | $25,000 - $100,000 |

| Recycled Paper Inventory | $20,000 - $60,000 |

| Staffing & Payroll | $35,000 - $100,000 |

Although you spend more at first, you gain long-term savings. Eco friendly paper bag making machine: cost - benefit analysis reveals that energy-efficient equipment lowers your utility bills. Automated processes reduce labor costs and improve production speed. You also avoid fines or penalties because you meet environmental regulations.

You add value to your business by using sustainable materials and clean production. Customers prefer eco-friendly packaging, so you attract more buyers and build a stronger brand. Over time, your investment pays off through higher efficiency, lower waste, and increased sales.

You support sustainability and meet market demand.

You save money on energy and labor.

You improve your company’s reputation.

Tip: Eco friendly paper bag making machine: cost - benefit analysis helps you see that the benefits outweigh the costs, especially as more consumers choose green products.

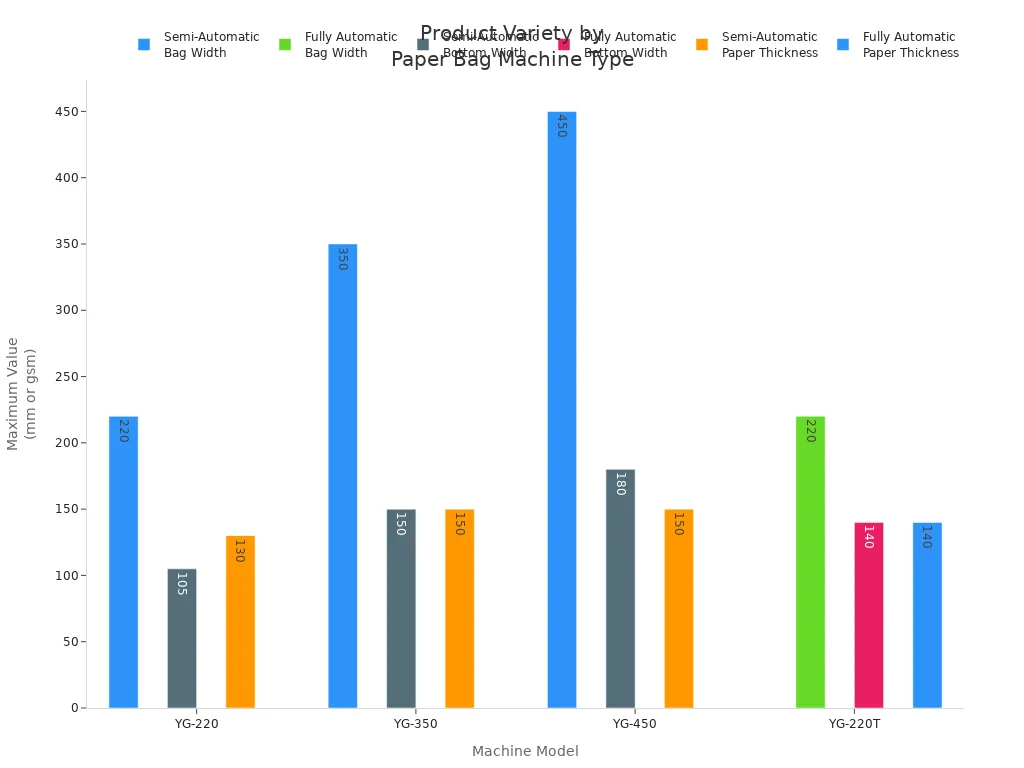

You want your business to offer a wide range of packaging solutions. The type of paper machines you choose affects the variety of products you can make. Semi-automatic machines like the ZB1200CT-430 let you create different sizes of paper bags. You can adjust the width from 180 to 430 mm and the bottom gusset from 80 to 170 mm. These machines handle paper thicknesses between 120 and 250 gsm. They perform several steps, such as sheet feeding, creasing, and square bottom gluing. This flexibility helps you meet customer needs for different packaging sizes.

You can see how different models compare in the table below:

| Machine Type | Model | Bag Width (mm) | Bottom Width (mm) | Paper Thickness (gsm) | Special Features | Production Speed (pcs/min) |

|---|---|---|---|---|---|---|

| Semi-Automatic | YG-220 | 220 | 50-105 | 50-130 | Standard square paper bags | 30-200 |

| Semi-Automatic | YG-350 | 120-350 | 60-150 | 60-150 | Standard square paper bags | 30-180 |

| Semi-Automatic | YG-450 | 210-450 | 90-180 | 80-150 | Standard square paper bags | 30-150 |

| Fully Automatic | YG-220T | 140-220 | 60-140 | 50-140 | Includes handle patching, pinking cutter | 30-200 (bag), 30-150 (handle) |

Fully automatic machines add even more options. Some models include handle patching and special cutting methods. You can produce bags with handles or unique shapes. This feature is important if you want to serve retail or food packaging markets. The chart below shows how bag width, bottom width, and paper thickness compare for different machines:

Note: Choosing the right paper machines lets you respond quickly to new trends in packaging and meet special requests from customers.

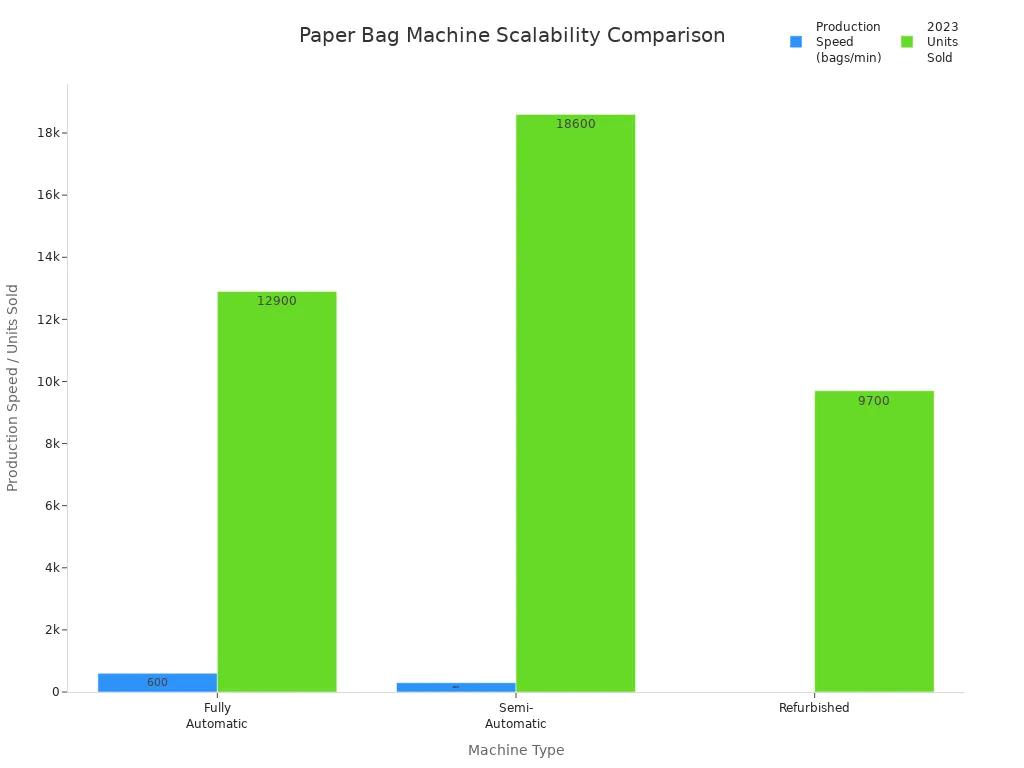

As your business grows, you need machines that can keep up with higher demand. Fully automatic paper machines offer high production speeds, reaching up to 600 bags per minute. These machines work best for large-scale packaging operations. They use advanced features like AI and IoT technology. You can reduce labor costs by 38% and increase throughput by 25%. This makes it easier to expand your business without hiring more workers.

Semi-automatic machines also support growth, especially for small and medium businesses. They produce 180 to 300 bags per minute. Many companies in Southeast Asia and Africa choose these machines because they are cost-effective. You can start small and add more machines as your orders increase. Refurbished machines give you another way to grow without spending too much at first, but they may not offer the latest energy-saving features.

Here is a table that compares scalability factors:

| Machine Type | Production Speed (bags/min) | Target Market | Scalability Factors |

|---|---|---|---|

| Fully Automatic | Up to 600 | Large-scale, high-output sectors | High throughput, minimal human intervention, supports multi-substrate use, integrated AI and IoT tech |

| Semi-Automatic | 180–300 | SMEs, local manufacturers | Cost-effective, strong growth in emerging markets, slower adoption of advanced tech |

| Refurbished Machines | N/A | Small and medium businesses | Lower initial cost, limits scalability for smaller businesses |

You can see the difference in production speed and market adoption in the chart below:

Tip: If you plan to expand your packaging business, invest in machines that match your growth goals. Fully automatic machines help you scale quickly, while semi-automatic machines let you grow step by step.

You must think about space when you choose a paper bag machine. The size of your machine affects how much room you need in your facility. Fully automatic paper bag machines usually take up much more space than semi-automatic models. These machines have higher production capacity and include extra features, so they are larger and heavier. You need to plan for the machine itself, but you also need space for raw materials and finished bags. If you want to run a large operation, you may need a dedicated area or even a separate building.

Semi-automatic machines work better for small businesses or workshops with limited space. These machines are smaller and often portable. You can fit them into a corner of your shop or a small production room. You do not need to make big changes to your workspace. This makes semi-automatic machines a good choice if you want to start small or if you have a tight budget for rent or construction.

Tip: Always measure your available space before you buy a machine. Make sure you leave enough room for workers to move safely and for storing both raw materials and finished products.

Here is a quick comparison:

| Machine Type | Space Requirement | Suitability |

|---|---|---|

| Fully Automatic | Large, needs more room | Large factories, high output |

| Semi-Automatic | Small, portable | Small businesses, workshops |

You must follow important rules when you operate paper bag machines. Both semi-automatic and fully automatic machines must meet strict standards in major markets. These rules protect the environment, your workers, and your customers.

First, you need to use safe and eco-friendly materials. Many countries ban harmful chemicals like PFAS in food packaging. You should choose unbleached kraft paper and water-based adhesives. These materials help you make bags that are recyclable and safe for the environment.

Second, you must keep your workplace safe. OSHA requires you to follow lockout/tagout standards. This means you must guard your machines and control hazardous energy. You need to train your workers to use the machines safely and to shut them down properly during maintenance.

Note: Meeting these standards is not just about following the law. It also helps you build trust with your customers and protects your business from fines or shutdowns.

You can use this checklist to help you stay compliant:

Use recyclable, eco-friendly materials.

Avoid banned chemicals in your products.

Install proper machine guards.

Train workers on safety procedures.

Keep records of safety checks and maintenance.

By following these rules, you make your business safer and more sustainable. You also show your customers that you care about quality and responsibility.

You now see that semi-automatic machines work best for small businesses or custom orders, while fully automatic machines suit large-scale, high-volume production. Remember to match your machine choice to your business size, budget, and production needs.

Weigh both initial and ongoing costs, not just the purchase price.

Consider maintenance, labor, and energy expenses.

Avoid overinvesting in capacity you cannot use.

Tip: Balance price and quality, and always plan for future growth to ensure long-term success.

You pay less upfront for semi-automatic machines. Fully automatic machines cost more at first but save you money on labor over time. Consider your budget and production needs before you choose.

Semi-automatic machines fit in small workshops or tight spaces. Fully automatic machines need more room because they are larger and have extra features. Always measure your space before you buy.

Yes, you can start with a semi-automatic machine and upgrade as your business grows. Many manufacturers offer trade-in programs or discounts for returning customers.

Semi-automatic machines work best for custom sizes or small batches. You can adjust settings quickly and switch between bag types with less downtime.

You should perform basic maintenance weekly. Fully automatic machines may need professional servicing every few months. Regular care helps prevent breakdowns and extends machine life.

Eco-friendly machines may cost more to buy, but they use less energy and create less waste. Over time, you save money on utilities and materials.

Workers learn to use semi-automatic machines quickly. Fully automatic machines require more training because of advanced controls. Many suppliers offer training sessions or manuals.

Yes, both machine types can use recycled paper. Check the machine’s specifications to make sure it handles the thickness and quality of recycled materials.