- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-07 Origin: Site

You operate an automatic paper bag making machine by loading paper rolls, setting up printing, and letting the system handle the rest. The machine feeds, glues, folds, cuts, and stacks bags with remarkable precision. You benefit from high-speed production, as some models create up to 125 bags per minute and can reach design speeds up to 200 bags per minute. The step-by-step process uses advanced automation, which means you get consistent results every time. Here is a quick look at key specifications:

| Specification | Value |

|---|---|

| Capacity | 70 to 125 bags per minute |

| Design Speed | Up to 200 bags per minute |

| Automation Grade | Automatic / Semi-Automatic |

| Bag Size Range | 7x15 cm to 42x60 cm |

A fully automated paper-making machine saves you time and labor, making the paper bag making machine an essential tool for modern packaging.

Automatic paper bag making machines turn large paper rolls into finished bags through precise, automated steps like feeding, printing, gluing, folding, cutting, and stacking.

These machines use advanced components such as servo motors, sensors, and touchscreen controls to ensure smooth operation and high accuracy.

You can customize bags by adjusting size, adding prints, or attaching different handle types, all controlled easily from the machine’s interface.

High-speed production lets you make up to 200 bags per minute, boosting efficiency and helping meet large orders quickly.

Automation reduces labor costs, minimizes waste, and maintains consistent bag quality with real-time error detection.

Regular maintenance and quality checks keep the machine running smoothly and extend its lifespan.

Using these machines supports eco-friendly packaging by producing recyclable, biodegradable bags with less energy and waste.

The modular design allows you to switch features like printing or handle attachment on or off, giving flexibility for different bag styles.

You start the paper bag making machine by loading a large roll of paper onto the paper roll feeder. This component acts as the entry point for raw materials. The feeder uses servo motors to control the speed and tension of the roll paper feeding process. The dancer system keeps the paper taut, preventing slack or tearing. You benefit from high precision and velocity control, which ensures that each sheet enters the machine smoothly. Integrated conveyors and sensors help guide the paper, making sure it stays aligned. The feeder’s design allows you to switch paper rolls quickly, reducing downtime and boosting productivity. Safety systems, such as light curtains and obstruction detection, protect you during operation.

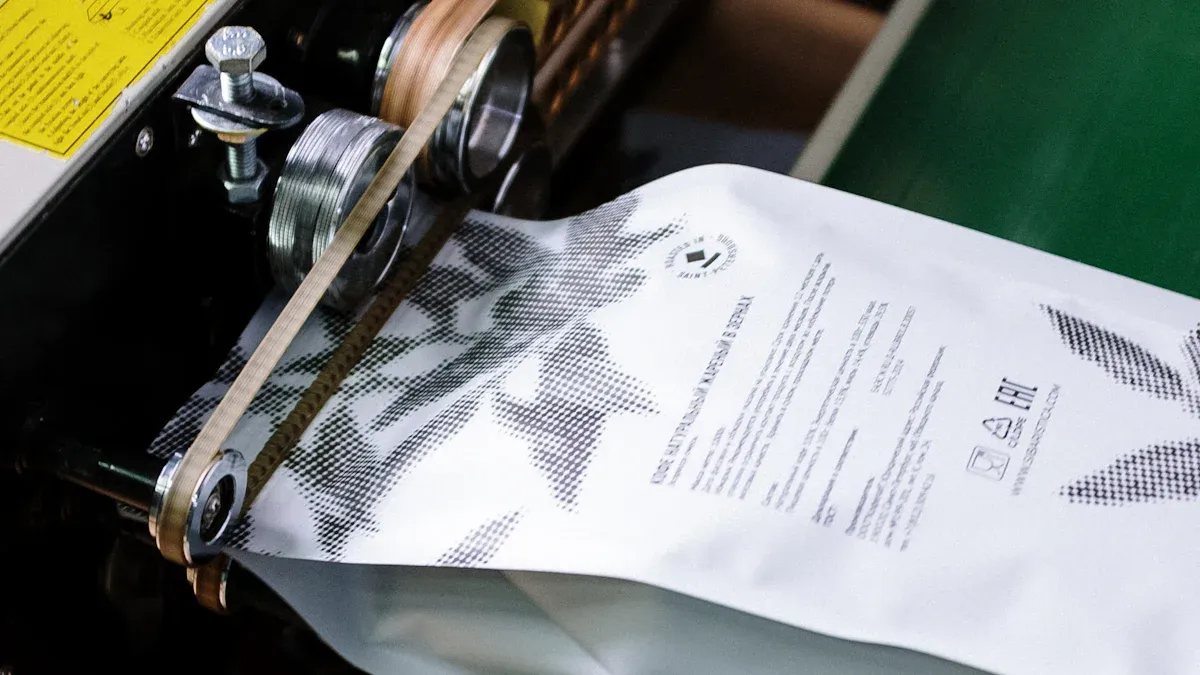

Once the paper feeds into the machine, it moves to the printing unit. Here, you can add custom designs, logos, or branding to your bags. The printing unit uses advanced technology to apply ink evenly and accurately. You control the printing process through a color touchscreen interface, which lets you set parameters like print position and color. This interface also allows you to monitor the printing quality in real time. The printing unit supports both single-color and multi-color printing, giving you flexibility for different bag designs. You can integrate this unit with robotics and feeding systems, which demonstrates the machine’s interoperability. The printing unit’s precision engineering ensures that every bag looks professional and consistent.

Tip: You can skip the printing step if you want plain bags. The machine’s modular design lets you turn the printing unit on or off as needed.

After printing, the paper moves to the gluing system. This part of the paper bag making machine applies adhesive to specific areas, such as the bag’s bottom or side seams. The gluing system uses valve technology to distribute glue evenly, ensuring strong seals. You benefit from self-diagnostics that alert you to any issues, reducing maintenance time. The system’s design allows for quick adjustments, so you can change glue patterns or amounts based on bag size. Pneumatic lifting systems help control the pressure and positioning of the glue applicators. This working mechanism guarantees that each bag is sealed securely and ready for the next step. Off-the-shelf components make repairs and replacements simple, keeping your machine running smoothly.

Key features of these main components include:

High-precision servo motors for accurate material feeding

Touchscreen controls for easy operation and monitoring

Integrated safety and self-diagnostic systems for reliability

The folding mechanism shapes the flat paper into a bag form. You see this part of the paper bag making machine work with great accuracy. Rollers and guides move the paper along a set path. The machine folds the sides and bottom of the paper. Sensors check the position of the paper at each step. You can adjust the folding width and length using the control panel. This flexibility lets you create bags of different sizes.

The folding mechanism uses a combination of mechanical arms and air jets. These parts help crease the paper sharply. You get clean, straight edges every time. The working mechanism here relies on precise timing. Each fold happens at the right moment, so the paper does not jam or tear. If you want to change the bag style, you can switch settings quickly.

Note: The folding mechanism often includes safety covers. These covers protect your hands from moving parts.

After folding, the paper moves to the cutting device. This part cuts the continuous paper into individual bags. You control the cutting length from the touchscreen. The cutting device uses sharp rotary blades or knives. These blades slice through the paper cleanly. You get uniform bag sizes with every cycle.

Sensors in the cutting device check the paper’s position before each cut. If the paper is not aligned, the machine stops and alerts you. This feature helps prevent waste. Some machines use servo motors to control the speed and force of the blades. You can adjust these settings for different paper thicknesses.

Key features of the cutting device:

High-speed rotary blades

Adjustable cutting length

Safety sensors to prevent accidents

Once the bags are cut, they move to the stacking and collection area. Here, the paper bag making machine organizes finished bags into neat piles. Robotic arms or conveyors guide the bags into stacks. You can set the stack height and number of bags per stack.

A table below shows what you can control in the stacking and collection section:

| Feature | What You Control |

|---|---|

| Stack Height | Number of bags per pile |

| Collection Speed | How fast bags stack |

| Output Location | Where stacks go |

You remove the finished stacks for packing or shipping. The stacking system keeps your workspace tidy. It also reduces the time you spend handling bags by hand.

Tip: Some machines let you add a handle attachment step after stacking. This feature gives you more options for bag styles.

The handle attachment unit gives you the option to add handles to your paper bags automatically. This feature is especially useful if you want to produce shopping bags or gift bags that customers can carry easily. The handle attachment system works right after the main bag body forms and before the bags move to the stacking area.

You start by loading handle materials into the machine. These materials can be twisted paper ropes, flat paper strips, or even reinforced paper handles. The machine pulls the handle material from a separate roll or feeder. Robotic arms or precision grippers cut the handle material to the correct length. The system then applies glue to the ends of each handle.

Next, the machine positions each handle onto the bag. Sensors and cameras guide the placement, making sure every handle sits in the same spot on each bag. You can adjust the handle position and length using the touchscreen control panel. This flexibility lets you create bags with different handle styles or sizes.

Tip: If you do not need handles, you can turn off the handle attachment unit. The modular design of most machines allows you to switch between bag types quickly.

The handle attachment process uses several advanced features:

Servo motors control the movement and placement of handles for high accuracy.

Sensors check the position of each handle and the amount of glue applied.

Self-diagnostic systems alert you if a handle is missing or misaligned.

Quick-change fixtures let you swap handle types or sizes without long delays.

Here is a table showing what you can control in the handle attachment section:

| Feature | What You Control |

|---|---|

| Handle Type | Rope, flat, or reinforced |

| Handle Length | Adjustable by user |

| Handle Position | Set placement on each bag |

| Glue Amount | Fine-tune for strong adhesion |

| Attachment Speed | Match with bag production speed |

You benefit from this automation in several ways. You save time because you do not need to attach handles by hand. You get consistent results, as every handle sits in the same place and holds firmly. The machine can attach handles at high speeds, keeping up with the rest of the bag-making process.

If you want to produce bags for retail, groceries, or gifts, the handle attachment unit makes your operation more versatile. You can meet different customer needs without slowing down production. The integration of robotics and sensors ensures that every bag is ready for use as soon as it leaves the machine.

Note: Regular cleaning and inspection of the handle attachment unit help maintain smooth operation and prevent glue buildup.

You begin the step-by-step process of paper bag making by loading a large roll of paper onto the feeder. The paper bag making machine uses sensors and servo motors to pull the paper smoothly and keep it tight. This step ensures the paper does not wrinkle or tear as it moves through the machine. You can adjust the tension and speed using the control panel. The feeder checks the paper’s position and keeps it aligned, so every bag starts with a perfect sheet. This step sets the foundation for the rest of the process.

Next, you move to the printing and designing stage. Here, you can add your logo, brand name, or any custom design to the paper. The printing unit uses advanced technology to apply ink with high precision. You control the printing settings from a touchscreen, choosing the color, position, and size of your design. The machine supports both single-color and multi-color printing, giving you flexibility for different bag styles.

The vision system in the paper bag making machine tracks each sheet in real time. It checks the accuracy of the printing, making sure every design lines up perfectly. The system achieves an average detection accuracy of 96.8% and keeps tracking errors as low as 1.5 mm. This high level of precision means your bags always look professional and consistent.

Tip: You can skip the printing step if you want plain bags. The modular design lets you turn the printing unit on or off as needed.

After printing, the paper moves to the gluing application stage. The machine applies glue to specific areas, such as the sides and bottom of the bag. You can adjust the amount and pattern of glue using the control panel. The gluing system uses valves and sensors to make sure the glue spreads evenly and only where needed. This step creates strong seams that hold the bag together.

The gluing system also checks for any problems during operation. If the glue runs low or a nozzle gets blocked, the machine alerts you right away. This feature helps you avoid waste and keeps the step-by-step operation running smoothly.

Note: Consistent glue application is key to making sturdy bags that do not fall apart during use.

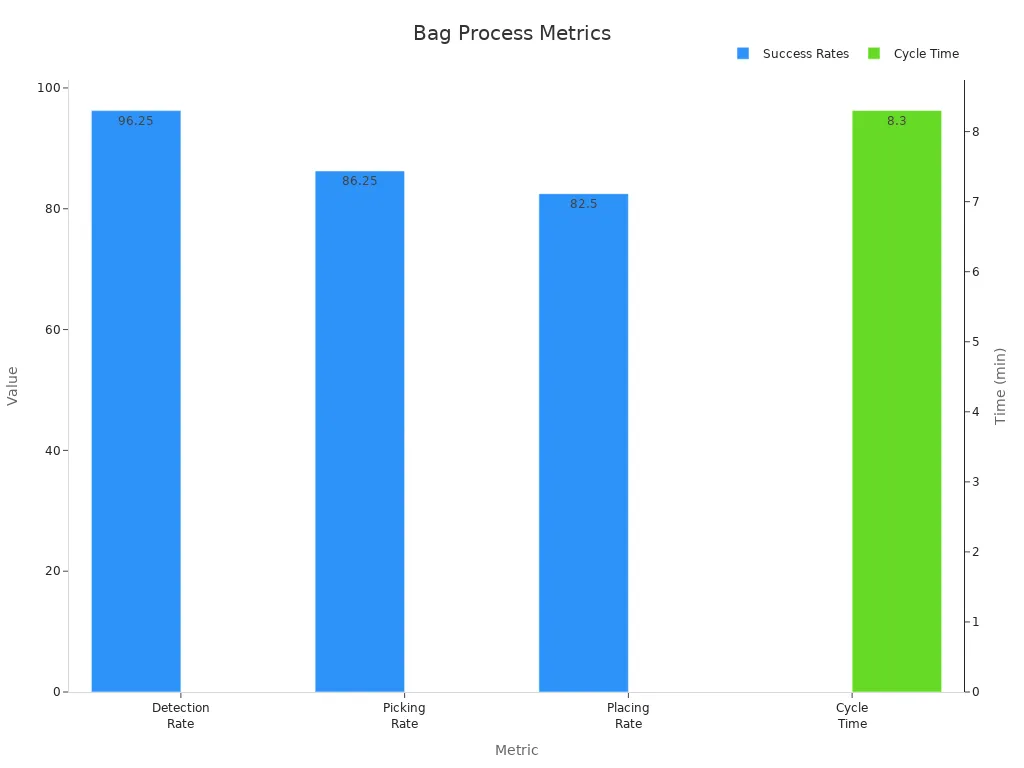

The chart above shows how the robot feeding system performs during the handling process. You can see high success rates for detection, picking, and placing bags, which proves the reliability of the separation and stacking systems later in the process. The average cycle time remains steady, helping you maintain a fast and efficient workflow.

You now reach the folding and shaping stage. This step is where the flat sheet of paper transforms into a bag. The machine uses a series of rollers, guides, and plates to fold the paper along precise lines. You watch as the sides fold inward, creating the classic bag shape. The bottom of the bag also folds up, ready for sealing.

Sensors track the position of the paper at every moment. If the paper moves out of place, the machine stops and alerts you. You can adjust the folding width and length using the control panel. This flexibility lets you create bags in many sizes. The folding mechanism uses both mechanical arms and air jets. These tools help crease the paper sharply and keep the edges straight.

You see the importance of timing in this step. Each fold must happen at the right moment. If the timing is off, the paper may jam or tear. The machine’s design helps prevent these problems. You can switch settings quickly if you want to change the bag style. This step is the heart of paper bag forming, where the flat material becomes a three-dimensional product.

Tip: Always check the folding guides for dust or debris. Clean guides help keep folds sharp and accurate.

After folding and shaping, you move to the cutting and separation stage. The machine now cuts the continuous paper into individual bags. Sharp rotary blades or knives slice through the paper with precision. You set the cutting length on the touchscreen. This control lets you choose the exact size for each bag.

Sensors check the alignment of the paper before each cut. If the paper is not in the right spot, the machine pauses and warns you. This feature helps you avoid waste and keeps every bag the same size. Some machines use servo motors to control the speed and force of the blades. You can adjust these settings for different paper thicknesses.

You may notice that the cutting device works very fast. High-speed blades allow the machine to keep up with the rest of the process. You get uniform bags every time. If you want to change the bag size, you only need to update the settings on the control panel.

Note: Always inspect the blades for sharpness. Dull blades can cause rough edges or uneven cuts.

The final step is finishing and stacking. Once the bags are cut, the machine organizes them into neat piles. Robotic arms or conveyors move the bags into stacks. You can set the stack height and the number of bags per pile. This control helps you prepare bags for packing or shipping.

The stacking system keeps your workspace tidy. You do not need to handle each bag by hand. The machine does the work for you. Some machines let you add a handle attachment step before stacking. This option gives you more choices for bag styles.

You can monitor the stacking process on the control panel. If a stack reaches the set height, the machine alerts you to remove it. This system helps you keep production moving smoothly. Finished bags come out clean, flat, and ready for use.

Tip: Regularly check the stacking area for jams or misaligned bags. Quick checks help prevent slowdowns.

You experience impressive speed when you use an automatic paper bag making machine. These machines can reach production speeds up to 80 bags per minute, like the AUTOBAG® PaceSetter PS 125™, or 45 bags per minute with the AUTOBAG® 550™ Bagging System. Some models even produce up to 100 bags per minute, giving you a high production rate that meets large orders quickly. The machine uses conveyors to move paper smoothly through each stage. Servo motors and automatic control systems keep the process running without long stops. You can rely on these machines to deliver thousands of bags per hour, which boosts your production capacity and helps you meet tight deadlines.

Tip: High-speed operation does not mean you lose control. You can adjust the speed and bag size from the control panel at any time.

Here is a quick look at some key performance metrics:

| Metric | Value |

|---|---|

| Production Speed | 30-100 pieces per minute |

| Average Power Consumption | 20KW |

| Bag Length Range | 300-580mm |

| Bag Width Range | 220-580mm |

You benefit from full automation when you use an automatic paper bag making machine. The machine handles every step, from feeding and printing to gluing, folding, cutting, and stacking. Sensors check each part of the process, so you do not need to watch every detail. Automated sealing systems, such as heat or ultrasonic sealing, close each bag quickly and securely. Integrated printing systems let you add labels or designs without slowing down the line.

You save labor costs because the machine does most of the work.

You reduce errors since sensors and controls catch problems early.

You use less energy because modern machines have energy-efficient parts.

The efficiency of the paper bag-making machine means you can produce bags with or without handles in one continuous pass. You do not need to stop the machine to change bag styles. This flexibility lets you fill different orders without wasting time.

You always get high-quality paper bags when you use an automatic paper bag making machine. The machine uses sensors to check the position and quality of each bag. If something goes wrong, the machine alerts you right away. Automated systems apply glue, fold paper, and cut bags with the same precision every time. This consistency means your customers receive bags that look and perform the same with every order.

You can trust the machine to handle different paper thicknesses, from 35g to 120g, and still deliver strong, neat bags. Automated error detection and precise filling help you avoid waste and keep your products looking professional. The integration of multiple steps in one pass supports stable operation and reliable results.

Note: Consistent quality helps you build trust with your customers and grow your business.

Automatic paper bag making machines give you the ability to produce many types of paper bags. You can choose the style, size, and features that fit your needs. The machine’s flexibility lets you switch between bag types quickly, so you can meet different customer demands.

Flat bags are one of the most common types of paper bags you can make. These bags have a flat bottom and straight sides. You often see them used for groceries, bakery items, or takeout food. The machine forms these bags by folding and gluing the paper into a sturdy shape. You can select different sizes, from small snack bags to large shopping bags.

Production speeds for flat bags can reach up to 220 bags per minute, depending on the machine model. Some machines, like the RZFD-330, let you adjust the bag length from 270 mm to 530 mm and the width from 120 mm to 330 mm. You can also add features such as die-cut windows or plastic strip windows for special uses.

Tip: Flat bags can carry heavy loads—up to 10 kg—when you use strong adhesives and proper folding techniques.

If you want to offer more convenience, you can produce bags with handles. These bags are perfect for retail stores, gift shops, and food delivery. You can choose from several handle types, such as flat paper handles, twisted handles, or die-cut handles. The machine attaches handles automatically, so you do not need to add them by hand.

Some models, like the RZFD-330T, can make flat bottom bags with twisted handles at speeds up to 180 bags per minute. You can adjust the handle type and position using the control panel. The handle making unit works inline, which means you do not have to stop the machine to change styles. This feature helps you keep up with large orders and tight deadlines.

Here is a table that compares different machine models and their bag-making capabilities:

| Machine Model | Bag Type | Production Speed (bags/min) | Bag Size Range (L x W x Bottom mm) | Handle Types Available | Customization Features |

|---|---|---|---|---|---|

| RZFD-330 | Flat Bottom Paper Bags | Up to 220 | Length: 270–530, Width: 120–330 | Flat, Twisted, Die-cut (patch) | Inline printing, die-cut windows |

| RZFD-330T | Flat Bottom with Twisted Handles | 30–180 | Length: 270–760, Width: 120–330, Bottom: 70–180 | Twisted handles | Inline printing, handle making unit |

| RZFD-190 | Small-sized Flat Bottom Bags | 30–240 | Length: 190–370, Width: 80–200, Bottom: 50–105 | Flat, Twisted, Die-cut | Inline printing, die-cut window, plastic strip window, handle making unit |

Custom printed bags help you promote your brand or share important information with customers. You can print logos, slogans, or colorful designs directly onto the bag during production. The machine’s inline printing unit lets you change designs quickly, so you can create unique bags for different events or promotions.

You control the printing process from the touchscreen. You can select single-color or multi-color printing, adjust the print position, and even add die-cut windows for a special look. Custom printed bags are popular in retail, food service, and gift packaging. You can produce these bags in many sizes and styles, including both flat bags and bags with handles.

Note: The ability to customize bag size, handle type, and printing makes automatic machines ideal for producing all types of paper bags for different industries.

You keep your automatic paper bag making machine running smoothly by following a regular maintenance schedule. Each part of the machine needs attention at different times. You replace the screw and synchronous belt every month. The conveyor belt and braking device need replacement every three months. You change the photoelectric switch once a month. The puncture knife rollers require weekly replacement. You also replace the gear or grease spray every three weeks. Electrical parts need inspection twice a year. You clean the machine daily to prevent dust from building up. Regular lubrication keeps all moving parts working well.

Here is a simple table to help you remember the maintenance schedule:

| Component | Maintenance Frequency |

|---|---|

| Screw & Synchronous Belt | Monthly |

| Conveyor Belt | Every 3 months |

| Braking Device | Every 3 months |

| Photoelectric Switch | Monthly |

| Puncture Knife Rollers | Weekly |

| Gear/Grease Spray | Every 3 weeks |

| Electrical Parts | Twice a year |

| Cleaning | Daily |

| Lubrication | Regularly |

Tip: Set reminders for each maintenance task. This habit helps you avoid unexpected breakdowns and keeps your machine in top shape.

You ensure every paper bag meets high standards by following strict quality control steps. You inspect all materials and spare parts before using them. Each part gets a serial number, so you can trace it if needed. You use modern machines to make precision parts in-house. Assembly takes place in special workshops to keep everything clean and organized.

You manage spare parts with ERP software. This system helps you track inventory and respond quickly if you need replacements. Before you send out a new machine, you run it for a full week inside the factory. This test helps you find and fix any problems. You only deliver machines that meet the agreed product standards.

Quality control does not stop after assembly. You keep checking the machine during daily operation. You look for signs of wear, listen for unusual noises, and watch for any changes in performance. If you spot a problem, you fix it right away. This careful approach helps you produce reliable paper bags and keeps your customers happy.

Note: Careful inspection and regular maintenance work together to extend the life of your machine and improve your results.

You see automatic paper bag making machines in many industries today. These machines help you meet the growing demand for sustainable packaging solutions. You can use them in packaging, printing, tissue products, and specialty papers. The machines work fast and reduce the need for manual labor. This means you save money and increase your output.

Here is how the automated process works in your factory:

You start by feeding paper rolls into the machine.

The machine forms the bags using temperature-controlled sealing.

Sharp blades cut the paper into precise shapes.

Gluing systems attach the pieces together both lengthwise and across.

The machine folds the ends to finish the bag shape.

Finished bags are stacked and moved for collection.

This sequence lets you produce large numbers of bags quickly. You get consistent quality with less waste. Modern machines also use IoT and AI for real-time monitoring and predictive maintenance. You can track production and fix problems before they slow you down.

Take a look at the table below to see the main benefits you gain from using these machines:

| Benefit Category | Quantifiable Benefit / Description |

|---|---|

| Productivity | High-speed and automated operations significantly increase production capacity and efficiency. |

| Labor Costs | Automation reduces the need for manual labor, lowering labor expenses. |

| Energy Efficiency | Modern machines incorporate energy-saving technologies, reducing power consumption. |

| Waste Minimization | Precision engineering and automation reduce material waste during production. |

| Market Growth | Market valued at $4.9 billion in 2024, projected to reach $7.8 billion by 2034, growing at 4.8% CAGR. |

| Technological Integration | Use of IoT, AI, and automation enables real-time monitoring, predictive maintenance, and operational efficiency. |

| Industry Applications | Widely used in packaging, printing, tissue products, and specialty papers industries, meeting growing eco-friendly packaging demand. |

Tip: You can boost your business by choosing machines that support eco-friendly manufacturing and advanced automation.

You help the planet when you use automatic paper bag making machines. These machines support eco-friendly manufacturing by using less energy and creating less waste. You can produce bags that are biodegradable and recyclable. This helps you reduce your reliance on single-use plastics.

The machines also use water recycling systems and fewer chemicals. This lowers your environmental impact and helps you follow sustainability practices. When you choose paper bags, you offer your customers a greener choice. You show that your company cares about environmental benefits and the future of the planet.

Here are some ways these machines support sustainability:

You use less energy because of energy-saving features.

You create less waste thanks to precise cutting and gluing.

You make bags that break down naturally and can be recycled.

You help reduce pollution by using fewer chemicals and recycling water.

Note: Many businesses now choose paper bags to show their commitment to sustainability and a cleaner environment.

You have seen how automatic paper bag making machines turn raw paper into finished bags through a series of precise, automated steps. By choosing the right machine, you ensure efficient production and meet your business needs. High-quality machines give you durable, reliable performance and help you deliver consistent, superior bags.

You support eco-friendly packaging, which matches what many customers want today.

You also help shape a future where technology and sustainability work together in the paper bag industry.

Take a moment to appreciate the advanced technology behind every simple paper bag you use.

You can expect most machines to make 70 to 200 bags per minute. The exact speed depends on the model and bag size. High-speed machines help you meet large orders quickly.

Yes, you can use recycled paper rolls. Make sure the paper meets the machine’s thickness and quality requirements. Using recycled paper helps you support eco-friendly production.

You do not need advanced training. Most machines have user-friendly touchscreens and clear instructions. You can learn basic operation and maintenance with a short training session.

You can add flat paper handles, twisted paper handles, or die-cut handles. The machine lets you choose the handle type and adjust its position. This flexibility helps you meet different customer needs.

You rely on sensors and automated controls. These systems check each step, from feeding to stacking. If the machine detects a problem, it alerts you. Regular maintenance also helps you keep quality high.

Yes, you can change bag size settings on the control panel. The machine adjusts folding, cutting, and gluing automatically. This feature lets you handle different orders without long delays.

You should stop the machine and check for paper jams or misaligned parts. Remove any stuck paper carefully. Restart the machine after clearing the problem. Regular cleaning helps you prevent jams.

Most modern machines use energy-saving motors and smart controls. You use less power compared to older models. This efficiency helps you lower production costs and reduce your environmental impact.