- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-25 Origin: Site

The Energy - Saving Features of Automatic Paper Bag Making Machine with Printing offer significant benefits for plant managers and business owners. With advanced automation, these machines require minimal human intervention and achieve higher production rates compared to older models. While the upfront cost of an automatic paper bag making machine with printing may be greater, the Energy - Saving Features of Automatic Paper Bag Making Machine with Printing ensure consistent quality and operational efficiency. Their energy-efficient design helps lower operating expenses over time and aligns with sustainability initiatives. By leveraging the Energy - Saving Features of Automatic Paper Bag Making Machine with Printing, companies can optimize both productivity and energy consumption, resulting in greater long-term value.

Modern automatic paper bag making machines include several energy-saving features that help manufacturers reduce costs and improve efficiency. These machines use advanced technology to minimize power consumption, lower greenhouse gas emissions, and support sustainable manufacturing practices. The energy - saving features of automatic paper bag making machine with printing focus on three main areas: efficient motors, variable speed drives, and optimized control systems.

Efficient motors play a key role in reducing the energy use of an automatic paper bag making machine. Manufacturers often select motors that meet the latest efficiency standards. These motors, such as ABB's IE5 SynRM, can cut energy losses and support decarbonization goals. By using less power, they help lower operational costs and reduce the environmental impact of production.

High-performance motors deliver reliable output while using less energy. They maintain consistent speed and torque, even during demanding production cycles. When paired with energy-efficient components, these motors can reduce total energy consumption by up to 30%. This improvement leads to significant savings for plant managers and supports the long-term sustainability of the operation.

Variable speed drives allow operators to adjust the speed of the motor based on production needs. This flexibility means the automatic paper bag making machine only uses as much energy as necessary for each task. By matching motor speed to the workload, the system avoids wasting power during low-demand periods.

Power optimization features in variable speed drives further enhance efficiency. These drives can recover energy during braking and reuse it within the system. This process, known as regenerative braking, helps reduce overall power consumption and supports the energy - saving features of automatic paper bag making machine with printing.

Optimized control systems use advanced sensors and detectors to monitor every stage of production. These systems ensure precise cutting, folding, and gluing, which minimizes errors and defective products. Operators can adjust machine settings in real time to maintain quality and reduce waste.

Control systems also help lower raw material consumption. For example, the detector system can identify defective tubes and allow operators to reuse previously wasted valve openings. This approach not only saves materials but also reduces the energy needed to produce each bag. As a result, the energy - saving features of automatic paper bag making machine with printing contribute to both cost reduction and environmental compliance.

Tip: Manufacturers who invest in automatic paper bag making machines with these energy-saving features often see a quick return on investment due to lower utility bills and improved production efficiency.

Key Energy-Saving Features at a Glance:

| Feature | Benefit |

|---|---|

| Efficient Motors | Lower power use, reduced costs |

| Variable Speed Drives | Adjustable speed, optimized energy use |

| Optimized Control Systems | Less waste, higher product quality |

| Automation & Smart Design | Fewer errors, consistent energy savings |

Modern automatic paper bag making machines with printing use:

Energy-efficient power consumption

Automation to reduce manual intervention

Digital printing to minimize waste

Robust, smart designs for consistent performance

These energy-saving features help companies align with sustainability goals and maintain a competitive edge in the packaging industry.

Automation stands at the core of modern manufacturing. In the context of an automatic paper bag making machine, advanced automation transforms repetitive tasks into streamlined, energy-efficient processes. This shift not only increases throughput but also reduces operational costs and waste.

Automated material handling systems in an automatic paper bag making machine manage the movement, feeding, and processing of raw materials with minimal human intervention. These systems rely on advanced automation to ensure each step operates at peak efficiency.

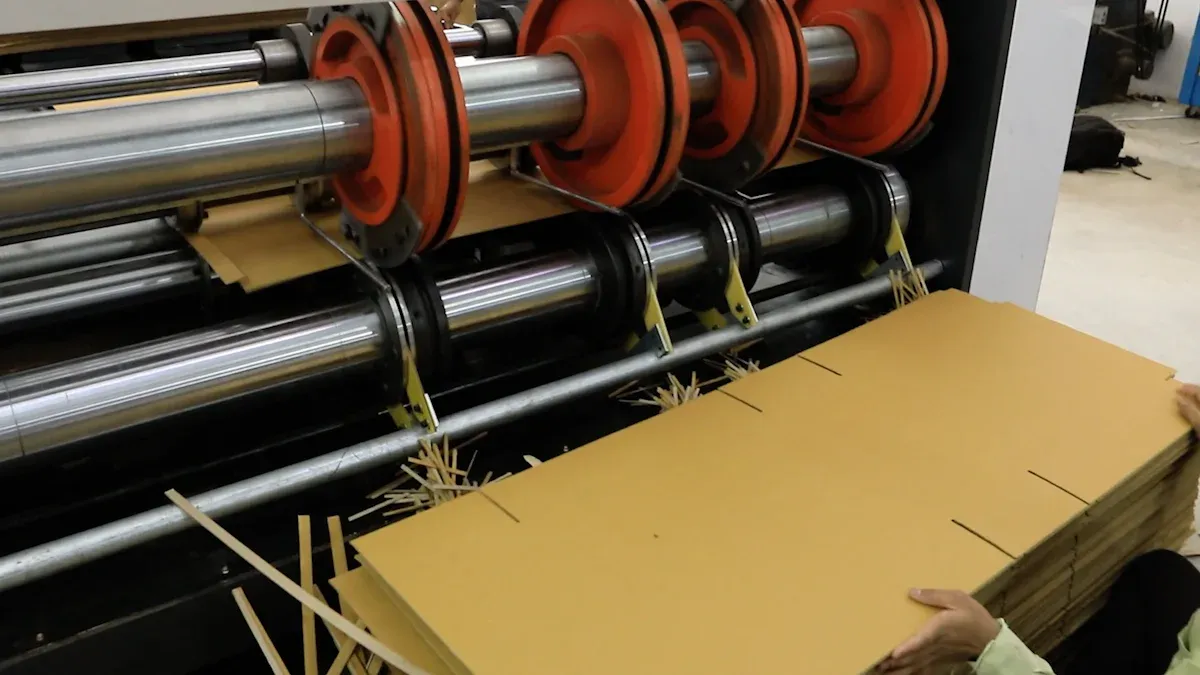

Automated feeding mechanisms deliver paper rolls into the machine at a consistent rate. Sensors and servo motors guide the material, ensuring precise alignment. The cutting unit, powered by electromechanical systems, slices the paper with high accuracy. This process reduces material waste and energy consumption compared to manual operations.

| Aspect | Manual Operations | Automated Systems |

|---|---|---|

| Energy Consumption | Standard (baseline) | Reduced by approximately 30% |

| Production Speed | Around 500 bags per hour | Over 2000 bags per hour |

| Material Waste | 15-20% | Reduced to 3-5% |

| Labor Costs | High | Reduced by 60% |

| Quality Consistency | Variable | High (99.5% accuracy) |

This table highlights the clear advantages of automation. The automatic paper bag making machine achieves faster production, lower waste, and significant energy savings.

After cutting, the machine moves the paper to the folding and gluing stations. Advanced automation ensures each fold and glue application is precise. Electromechanical actuators and intelligent controls maintain uniformity, which leads to fewer defects and less rework. The result is a consistent product and reduced energy use per bag.

Note: Automated systems in these machines operate independently, using motors that consume only 3 to 4 HP. This design supports continuous, high-speed production and minimizes energy waste.

Modern automatic paper bag making machines include energy-saving modes that further enhance efficiency. These features activate during periods of low demand or machine inactivity.

When the machine enters an idle state, energy-saving modes reduce power to non-essential components. Motors slow down or stop, and auxiliary systems enter standby. This approach can cut electricity consumption by up to 80% during downtime. Advanced automation and robotics help minimize idle times, keeping the machine ready for quick restarts.

Quick restart functions allow the machine to resume full operation almost instantly after an idle period. Intelligent controls monitor system status and prepare all components for immediate action. This feature prevents unnecessary energy spikes and supports continuous production without delays.

Key benefits of integrating automated material handling and energy-saving modes:

Lower electricity consumption through advanced energy management and ECO modes

Continuous operation with minimal idle time

Optimized tool paths and machine utilization

Real-time monitoring and predictive adjustments for energy use

Reduced cycle times and increased throughput

| Aspect | Description |

|---|---|

| Integration Model | Combines process planning and scheduling for optimal machine allocation |

| Energy Optimization | Uses predictive models and algorithms to minimize energy consumption |

| Impact on Throughput | Improves machine utilization and reduces cycle times |

| Impact on Energy Use | Reduces idle times and energy waste |

| Additional Measures | Includes on/off controls and speed adjustments for further energy savings |

Advanced automation in an automatic paper bag making machine, combined with energy-saving modes, delivers measurable improvements in efficiency. These systems enable manufacturers to produce more bags with less energy, lower costs, and greater consistency.

Direct branding through integrated printing units allows manufacturers to apply logos, graphics, and product information onto bags in a single step. This approach eliminates the need for separate printing stages, which often require additional machines and energy. Automation in printing lines increases speed and reduces errors. Operators can rely on real-time monitoring and data analysis to prevent delays and waste. Upgrading to advanced equipment optimizes each process, reducing unnecessary steps and defective products. These improvements help companies achieve consistent branding while lowering energy use.

Automation in printing increases production speed.

Smart scheduling and real-time monitoring prevent waste.

Advanced equipment reduces defective products and energy use.

Eco-friendly inks and water-based glues support environmental responsibility.

Direct branding also supports sustainable packaging by reducing the number of production steps and minimizing the use of energy-intensive materials.

Modern printing units use high-efficiency motors and digital controls to minimize power consumption. Implementing energy-efficient equipment can significantly reduce electricity use. Lean manufacturing techniques and Six Sigma methods help operators optimize production, which lowers waste and energy use. Digitalization, including IoT and data analytics, enables real-time monitoring and predictive maintenance. These tools improve equipment efficiency and reduce downtime. Studies show that optimizing production processes can reduce energy consumption by up to 25%. Digitalization also helps lower greenhouse gas emissions, supporting energy efficiency goals.

Tip: Using eco-friendly inks and recycling scraps further reduces the carbon footprint of printing operations.

Integrating the printing unit with other machine operations creates a seamless workflow. Automation enables precise control of print settings and ink usage, which reduces resource consumption. Centralized workflow management optimizes production, reducing idle times and energy use per printed bag. Real-time error detection and automatic quality control minimize defective prints. This approach ensures that each bag meets quality standards without wasting materials or energy.

Automation synchronizes printing with cutting, folding, and gluing.

Centralized management reduces idle time and energy consumption.

Real-time quality control lowers waste and improves consistency.

Automated systems in paper bag making machines help reduce electricity consumption and labor requirements. Predictive maintenance and remote monitoring decrease downtime and unnecessary resource use. Efficient machine utilization minimizes both energy use and material waste throughout the printing process. Waste management practices, such as recycling scraps and optimizing energy use, contribute to lower carbon footprints. These strategies support sustainable packaging and help companies meet environmental goals.

Note: Integration of printing with other operations not only saves energy but also improves overall production efficiency.

Proper setup of an automatic paper bag making machine starts with stable power settings. Operators should ensure a consistent power supply and consider backup options like generators to prevent unexpected downtime. Reliable electricity keeps the machine running smoothly and avoids costly interruptions. A logical workflow layout also helps minimize material handling time and prevents bottlenecks. This setup supports efficient production and reduces unnecessary energy use.

Accurate sensor calibration is essential for maintaining high production standards. Regular calibration allows the automatic paper bag making machine to detect and correct errors quickly. This process reduces waste and ensures each bag meets quality requirements. Operators should schedule routine checks to keep sensors functioning at their best. Well-calibrated sensors help the machine use only the energy needed for each task, which supports overall efficiency.

Tip: Regular calibration and a well-organized workspace can lower material waste and energy consumption.

Operator training plays a vital role in maximizing the efficiency of an automatic paper bag making machine. Comprehensive programs teach staff about machine functions, maintenance, and troubleshooting. Oyang, a leading manufacturer, offers detailed training that helps operators reduce downtime and improve productivity. Well-trained staff can quickly identify and fix issues, which keeps the machine running efficiently and prevents unnecessary energy use.

Training should also focus on energy awareness. Operators who understand how their actions affect energy consumption can make better decisions during production. The TAPPI standard recommends teaching operators about process variables, equipment operation, and process control. This knowledge helps staff optimize machine performance and maintain efficient operation. Regular refresher courses keep everyone up to date with the latest best practices.

Regular operator training can reduce downtime by about 25%.

Monitoring machine performance with real-time data can increase efficiency by 15%.

Routine audits help companies track the energy use of an automatic paper bag making machine. By monitoring performance data, managers can identify areas for improvement. Usage assessments reveal patterns in energy consumption and highlight opportunities to optimize settings. These audits also ensure that the machine continues to meet production and quality goals.

Upgrading equipment and software keeps the automatic paper bag making machine operating at peak efficiency. Managers should evaluate long-term operational costs, including energy use and maintenance, not just the initial investment. Choosing machines with advanced features like automation, touchscreen controls, and integration capabilities can further reduce waste and improve efficiency. Suppliers who offer strong after-sales support, including training and spare parts, help maintain high performance over time.

Note: Routine maintenance and timely upgrades prevent unexpected breakdowns and support continuous, energy-efficient production.

Plant managers often start by collecting baseline metrics before installing an automatic paper bag making machine with energy-saving features. They record the average energy consumption, production output, and operational hours of their current equipment. These numbers help create a clear starting point for comparison. Managers may use simple tools like energy meters or software that tracks machine performance. By understanding the baseline, they can measure improvements after upgrading to new machines.

Tip: Always document energy use and production rates for at least one month before making changes. This practice ensures accurate comparisons.

After installing the new machine, managers compare the new energy consumption data with the baseline. They calculate the difference in kilowatt-hours (kWh) used per bag produced. This calculation shows the direct impact of energy-saving features. Managers also review electricity bills to see the reduction in costs. Many companies find that energy-efficient machines lower their monthly expenses. Some use a simple formula:

Energy Savings ($) = (Old kWh - New kWh) × Electricity Rate

A table can help visualize the results:

| Metric | Before Upgrade | After Upgrade | Improvement |

|---|---|---|---|

| Energy Use (kWh/day) | 120 | 80 | 33% less |

| Bags Produced (day) | 4,000 | 4,500 | 12.5% more |

| Cost per Bag ($) | 0.03 | 0.02 | 33% less |

This table shows how energy-saving features can reduce both energy use and cost per bag.

Several companies have reported strong efficiency gains after switching to automatic paper bag making machines with energy-saving features. One packaging plant in Ohio saw a 30% drop in electricity use within the first three months. The plant also increased its daily output by 15%. These results came from using efficient motors, variable speed drives, and automated controls.

Operators noticed fewer machine stoppages and less material waste. The new system helped them meet production targets while using less energy.

Many businesses in the packaging industry now focus on energy efficiency. For example, a manufacturer in California adopted machines with advanced control systems and energy-saving modes. The company reduced its annual energy bill by $18,000. It also improved its reputation for sustainable packaging. These real-world examples show that investing in energy-saving technology leads to measurable benefits. Companies not only save money but also support environmental goals.

Energy-saving features in paper bag making machines help manufacturers cut electricity bills. These machines use less power during production, which leads to direct savings on energy costs. By reducing energy consumption, companies also lower their carbon footprint. Innovations in paper bag manufacturing focus on minimizing energy use and waste. This approach decreases the environmental impact of production and supports eco-friendly features. Using recyclable materials in these machines further boosts sustainability and helps create a circular economy.

Eco-friendly features in modern machines offer several environmental benefits over traditional methods.

Paper bags come from renewable resources, such as trees managed through sustainable forestry.

They are biodegradable and compostable, which reduces long-term pollution.

Paper bags can be recycled and reshaped into new products, conserving resources.

Reusing and recycling paper bags lowers landfill waste and helps protect wildlife.

Energy-efficient production methods improve the eco-friendly profile of paper bags by reducing water and energy use.

These eco-friendly features make paper bag production less harmful to the environment and support the shift toward sustainable packaging.

New technologies continue to improve energy efficiency in paper bag making machines. Automation with advanced features, such as real-time monitoring and predictive analytics, helps optimize production and reduce downtime. AI and machine learning play a key role in these improvements. They optimize material usage, increase production speeds, and ensure consistent quality. These smart controls lower energy consumption and support eco-friendly operations. For example, some high-speed machines now use AI to automate design processes and predict maintenance needs, which leads to fewer breakdowns and less wasted energy. AI integration in manufacturing also makes operations more cost-effective and reliable.

Tip: Companies that invest in AI and smart controls often see faster production, less waste, and better energy savings.

Manufacturers adopt eco-friendly features to meet environmental objectives and comply with industry regulations. Certifications like FSC and PEFC ensure responsible sourcing and environmentally conscious production. These certifications require companies to use energy-efficient equipment and reduce waste. As regulations evolve, more businesses choose machines with eco-friendly features to stay competitive and meet customer demand for sustainable packaging.

Future trends in the industry include higher automation, energy and material reduction, and faster order changes. These trends help companies save energy and support sustainability goals.

Manufacturers can maximize efficiency by using high-quality materials, adjusting machine parameters, and conducting regular maintenance. Operators should monitor real-time data and train staff to use energy-saving features effectively. These steps lower costs and support eco-friendly production. Automation and advanced controls help overcome challenges like high energy use. Companies that focus on eco-friendly practices and continuous improvement will lead in sustainable packaging.

Regular evaluation ensures ongoing progress and lasting benefits.

Modern machines use efficient motors, variable speed drives, and advanced control systems. These features help reduce energy use and improve production speed. Operators can also use automation and energy-saving modes to lower costs.

Automation reduces manual work and ensures each step uses only the energy needed. Machines handle feeding, cutting, folding, and gluing with high accuracy. This process lowers waste and saves electricity.

Yes. Energy-saving features help companies use less power and produce less waste. Many machines use recyclable materials and eco-friendly inks. These steps support sustainable packaging and reduce environmental impact.

Operators should calibrate sensors regularly, usually once a month or after any major maintenance. Proper calibration keeps the machine accurate and helps avoid waste.

Energy-saving modes reduce power to non-essential parts when the machine is not running. This feature can cut electricity use by up to 80% during downtime. Quick restart functions help resume work fast.

Managers can track energy use before and after installing new machines. They compare electricity bills and production data. Simple tables or charts help show improvements in cost and efficiency.

Yes. Operators need training to use new features and maintain high efficiency. Training covers best practices, machine settings, and energy awareness. Well-trained staff help keep machines running smoothly.

AI and smart controls now help optimize production and predict maintenance needs. These technologies lower energy use and improve reliability. Companies that use them often see better results and support sustainable packaging.