- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-29 Origin: Site

A simple paper bag-making machine stands out for its compact design and benefits of small paper bag making machine. Many models offer a compact footprint, lightweight build, and user-friendly controls. Manufacturers engineer these machines for space efficiency, easy mobility, quick changeover, and reinforced bag strength. Users often find adjustable settings, support for different paper types, and energy-efficient operation. The compact design and benefits of small paper bag making machine help small businesses maximize productivity in limited spaces.

A small paper bag making machine stands out for its compact footprint. Manufacturers design these machines to fit into limited spaces, making them ideal for small workshops or businesses with restricted floor area. The reduced size does not compromise performance, allowing users to produce high-quality bags efficiently.

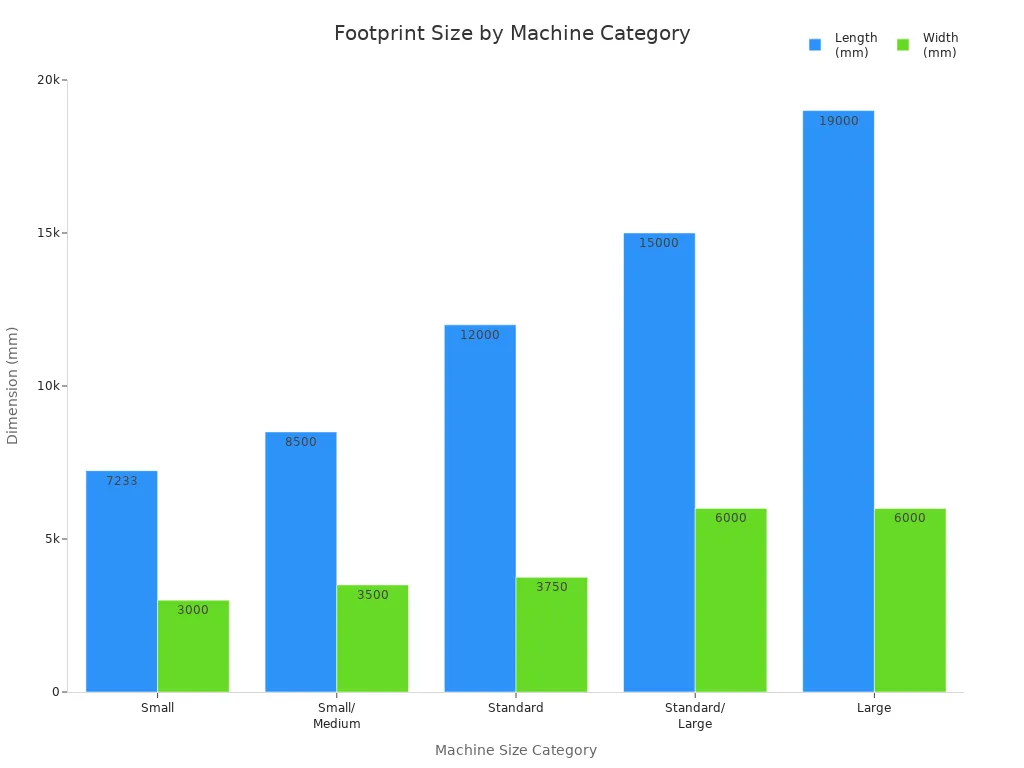

A compact footprint means the machine occupies less space on the shop floor. This allows operators to maximize available area for other essential equipment or storage. The following table compares the footprint dimensions of small and standard models:

| Machine Model | Footprint Dimensions (L x W in mm) | Size Category |

|---|---|---|

| RZJD-250J | 7100 x 3000 | Small |

| RZJD-350J | 7300 x 3000 | Small |

| RZJD-250J-2/4 Colors | 9600 x 3000 | Small |

| RZJD-190 | 8500 x 3500 | Small/Medium |

| RZFD-330D | 12000 x 3750 | Standard |

| RZFD-330T/450TA/450TB | 15000 x 6000 | Standard/Large |

| RZFD-330TF/450TFA/450TFB | 19000 x 6000 | Large |

Small machines typically measure between 7 and 9.6 meters in length and about 3 meters in width. Standard and large models can reach up to 19 meters long and 6 meters wide. This significant difference allows small machines to fit into spaces where larger equipment cannot.

A reduced footprint gives users more options for arranging their production area. Operators can place a compact paper bag making machine in corners, along walls, or even in mobile workstations. This flexibility supports efficient workflow and easy access to materials.

Tip: Flexible placement helps businesses adapt quickly to changes in production needs or shop layout.

Layout efficiency improves with smaller machines. Key benefits include:

Modular safety solutions for scalable, OSHA-compliant organization.

Improved workflow by aligning equipment with production flow.

Enhanced operator safety through guarded zones and walkways.

Quick reconfiguration to accommodate new machines or processes.

Increased capacity by fitting more equipment in the same space.

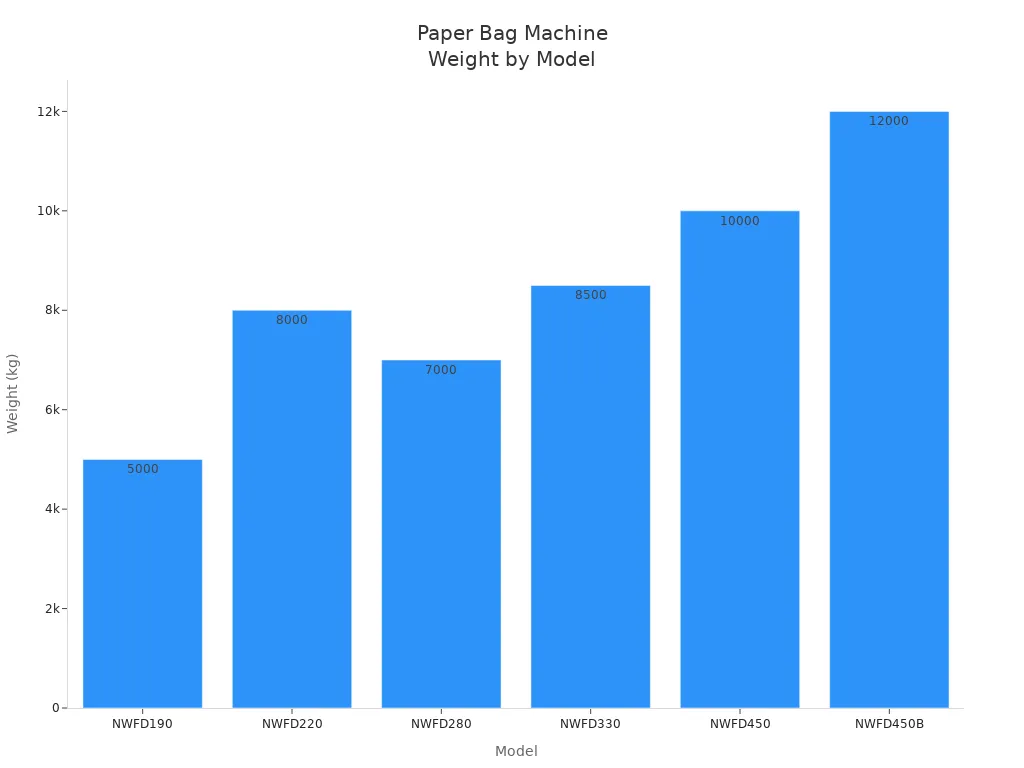

Small paper bag making machines feature a lighter build compared to standard models. This design makes them easier to move and install, especially in facilities with limited lifting equipment. The table below shows typical weights for different models:

| Model | Weight (kg) |

|---|---|

| NWFD190 | 5000 |

| NWFD220 | 8000 |

| NWFD280 | 7000 |

| NWFD330 | 8500 |

| NWFD450 | 10000 |

| NWFD450B | 12000 |

A lighter machine simplifies installation and relocation. It also reduces the need for heavy-duty flooring or support structures, making it suitable for a variety of packaging environments.

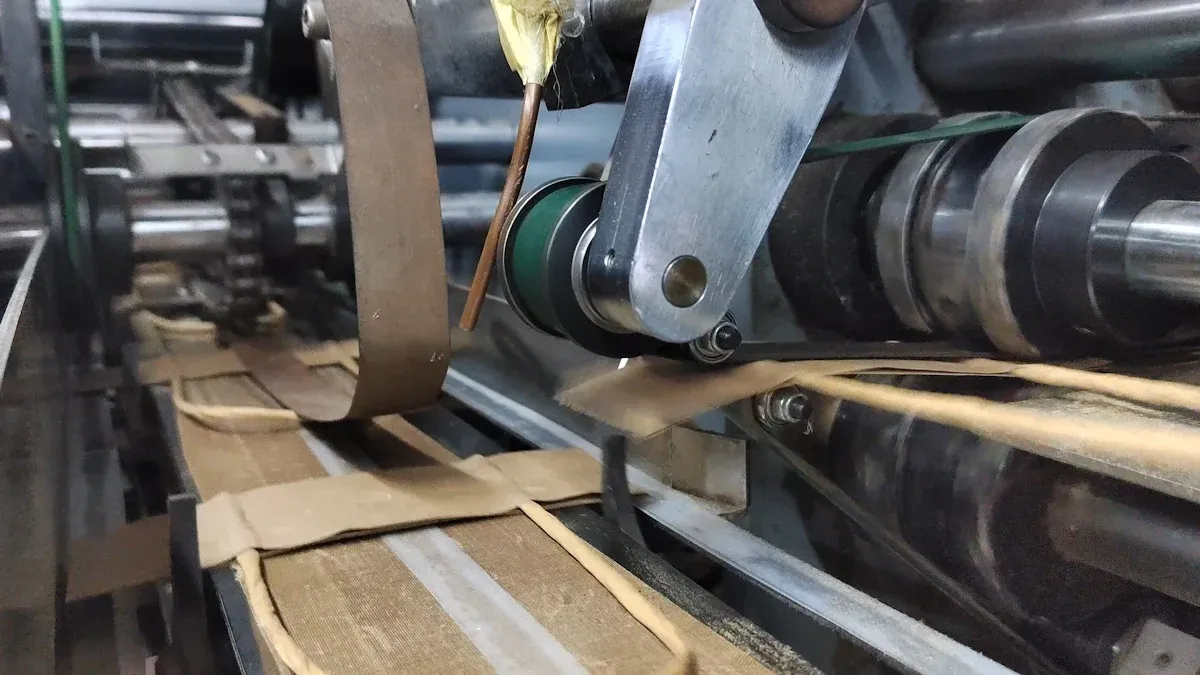

Manufacturers often equip small paper bag making machines with mobility features such as wheels and handles. These additions allow operators to move the machine easily for cleaning, maintenance, or layout changes. Wheels also play a role in the internal operation of the machine, helping to maintain material tension and guide paper through the forming process.

Mobility increases operational flexibility in small production environments. Key advantages include:

Agile movement between workstations for small-batch production.

Quick reconfiguration to support different packaging tasks.

Reduced downtime during changeovers or maintenance.

Improved adaptability to changing production schedules.

A mobile, compact machine helps businesses respond quickly to new orders or changes in bag design, supporting efficient packaging operations.

Fast changeover stands out as a key feature in modern compact machines. Operators can switch between different bag sizes or types quickly. The MTED Food Paper Bag Making Machine, for example, allows users to complete a changeover in about 45 minutes. This short changeover time results from a simplified structure and advanced design.

A fast changeover process helps businesses respond to new orders without long delays. Operators can adjust the machine for different packaging needs in less than an hour. This flexibility supports small batch production and custom orders. It also reduces downtime, which increases overall productivity.

Note: Quick changeovers help small businesses stay competitive by meeting customer demands for various bag sizes and styles.

A user-friendly interface makes operation simple for both new and experienced workers. Most compact machines feature clear control panels with labeled buttons and digital displays. Operators can set parameters, monitor progress, and troubleshoot issues with ease.

Touchscreen controls often guide users through each step of the process. Visual indicators show machine status and alert users to any problems. This design reduces training time and lowers the risk of errors.

Easy-to-read displays help operators track production.

Simple menus allow quick adjustments for different bags.

Safety features protect users during operation.

A user-friendly interface ensures that anyone can operate the machine with confidence. This feature is especially important for small businesses with limited staff.

Compact machines do not sacrifice quality for size. Many models include features that reinforce the strength of the bags they produce. These machines use precise folding, strong adhesives, and accurate cutting to create durable packaging.

Reinforced bag strength means that the finished product can hold heavier items without tearing. This is important for packaging food, retail goods, or specialty products. Strong bags reduce the risk of damage during transport and storage.

Some machines offer options for double-layered bottoms or extra glue lines. These enhancements increase the reliability of the bags. Customers receive packaging that protects their products and builds trust in the brand.

Tip: Reinforced bags help businesses avoid product loss and improve customer satisfaction.

Modern small paper bag making machines include advanced features that set them apart from basic models. These features help operators achieve higher quality, better efficiency, and more reliable results.

One standout feature is the photocell registration device. This technology works with pre-printed paper rolls. It detects printed marks on the material and aligns the cutting and folding processes with these marks. This ensures that every bag displays the design in the correct position. Operators see fewer printing errors and less wasted material. Machines with photocell registration produce bags with sharp, accurate graphics, which is important for branding and customer satisfaction.

Many compact machines also use ServoTech designs. Servo motors control the movement of paper and machine parts with high precision. This technology allows the machine to handle both plain and printed paper. Operators benefit from consistent bag sizes and shapes. ServoTech also supports quick adjustments, which helps when switching between different bag types.

PLC (Programmable Logic Controller) computer control is another advanced feature. The PLC acts as the brain of the machine. It manages timing, speed, and coordination of all moving parts. Operators use a digital interface to set up the machine and monitor its status. This system reduces human error and makes the machine easier to operate.

Photoelectric tracking systems further improve accuracy. These sensors detect the position of the paper and guide the machine to cut and seal at the right spots. This results in strong, even seals and clean cuts. Operators spend less time on manual adjustments. Production runs smoothly, and the quality of each bag remains consistent.

Other advanced options include:

Frequency motor drives for smooth speed control.

Automatic tension control to keep paper feeding steady.

Touchscreen panels for easy operation and quick troubleshooting.

Tip: Advanced features like photocell registration and ServoTech not only improve bag quality but also save time and reduce waste. Small businesses can deliver professional results without investing in large, complex equipment.

These innovations make compact paper bag making machines a smart choice for businesses that want high performance in a small package. Operators enjoy greater control, faster setup, and reliable output, all within a space-saving design.

Small paper bag making machines help businesses save valuable space. Their compact design allows operators to fit the equipment into tight areas, such as small workshops or home-based production rooms. Many small businesses do not have large manufacturing floors. They need machines that use every inch wisely. The compact design and benefits of small paper bag making machine become clear when comparing the space needed for different models. Operators can place these machines along walls, in corners, or even on mobile carts. This flexibility means more room for storing raw materials or finished bags. By saving space, businesses can increase their production capacity without moving to a larger facility.

Efficiency is a key benefit of compact paper bag making machines. These machines often feature streamlined workflows and easy-to-use controls. Operators can set up the machine quickly and start producing bags with minimal delay. Fast changeover times allow for quick adjustments between different bag sizes or styles. This is important for meeting the needs of customers who order high-demand paper bags. The compact design and benefits of small paper bag making machine also include reduced downtime. Maintenance tasks are easier because all parts are accessible. As a result, businesses can produce more packaging in less time. Efficient machines help companies keep up with orders and maintain a steady supply of bags for their clients.

Flexible layout options are essential in small manufacturing spaces. Compact machines support a variety of arrangements, making it easier to adapt to changing production needs. Manufacturers design these machines to maximize every square inch. Operators can create self-contained work cells where multiple tasks happen within a small footprint. This setup improves workflow and allows for quick changes if the business grows or shifts focus. Flexible material handling solutions, such as ceiling-mounted systems, further enhance adaptability. Equipment selection focuses on size and logical arrangement, which boosts productivity and safety. Multiple pathways for material flow allow operators to respond quickly to new packaging demands or industry trends.

Compact design maximizes use of limited space.

Layouts can expand or change with minimal disruption.

Work cells enable several tasks in a small area.

Flexible material handling improves workflow.

Logical equipment arrangement increases safety and productivity.

Multiple pathways allow fast responses to new production needs.

Tip: Flexible layouts help small businesses stay competitive by allowing them to adjust quickly to new orders or changes in the market.

Small businesses and startups often face unique challenges. They may have limited space, tight budgets, and a need for flexible equipment. Compact paper bag making machines address these needs directly. Their design helps entrepreneurs start or expand small-scale paper bag production without the barriers of large, expensive machinery.

One of the main reasons these machines work well for small businesses is their compact and space-efficient build. Owners can install them in home workshops, garages, or small rented spaces. There is no need for a large factory floor. This makes the compact design and benefits of small paper bag making machine especially valuable for those starting out in small towns or urban areas where space costs more.

Ease of operation is another key advantage. Many compact machines use simple manual or semi-automatic controls. Operators do not need advanced technical skills or long training sessions. Even beginners can learn to run the machine quickly. This reduces the need for hiring specialized staff, which saves money and time.

The ability to adjust bag sizes adds flexibility. Operators can change the length, width, or bottom fold to produce bags for different industries. This means a single machine can serve a variety of customers, from bakeries to boutiques. Small businesses can respond to changing market demands without buying new equipment.

Low power consumption also matters. Many compact machines run on single-phase power, which is common in homes and small shops. They use less electricity, so operating costs stay low. This helps small businesses keep more of their profits.

Manual gluing and cutting features allow for better control over adhesive use and waste. Owners can produce small batches or custom orders without extra expense. The machines often have a durable build with heavy-duty steel and corrosion-resistant parts. Maintenance is simple, so downtime stays minimal and repair costs remain low.

Affordable initial investment is another benefit. Compact machines cost much less than fully automatic models. Startups can begin production with a smaller budget and reach break-even faster. Optional add-ons, like punching tools or handle attachments, let businesses offer premium bags without a big jump in cost.

The table below highlights these features and explains why they matter for small businesses:

| Feature | Description | Why it Matters for Startups/Home Businesses |

|---|---|---|

| Compact and Space-Efficient | Small footprint allowing installation in home-based or small workshops. | No need for large factory space; ideal for home or small town entrepreneurs. |

| Ease of Operation | Simple manual or semi-automatic controls requiring minimal technical training. | Beginners can operate with little training; no need for specialized staff. |

| Adjustable Bag Sizes | Settings for length, width, and bottom fold size to produce various bag dimensions. | Enables serving diverse industries with one machine. |

| Low Power Consumption | Runs on single-phase power common in homes, consuming minimal electricity. | Reduces operational costs, boosting profit margins for small businesses. |

| Manual Gluing and Cutting | Allows manual or semi-automatic gluing and cutting to control adhesive use and reduce waste. | Keeps machine cost low and suitable for small-batch or custom production. |

| Durable Build and Low Maintenance | Made with heavy-duty steel and corrosion-resistant parts; easy to clean and maintain. | Less downtime and repair costs, focusing on production and delivery. |

| Affordable Initial Investment | Lower cost compared to fully automatic machines, starting under a few lakhs INR. | Low startup costs help faster break-even and organic business growth. |

| Optional Add-Ons | Optional punching tools and handle attachments for value addition without full automation. | Enables offering premium bags with minor add-ons, enhancing product appeal. |

Tip: Compact paper bag making machines help small businesses grow by lowering barriers to entry and supporting flexible, efficient production.

A simple paper bag-making machine offers straightforward installation. Most models use a manual, hand-operated design. Manufacturers build these machines with wood and basic metal parts. Operators only need common hand tools such as saws, files, pliers, and screwdrivers for assembly. The main folding machine often sits on a long wooden plank, about 254 centimeters in length and 20 centimeters wide. Guides and blocks attach directly to this plank for folding and guiding the paper. No special foundation or electrical supply is necessary. Operators can set up the equipment in small workshops, garages, or even home-based spaces. The installation process does not require dedicated space or strict environmental conditions. This minimal setup makes the simple paper bag-making machine ideal for small-scale production and quick relocation.

Tip: Operators can assemble and maintain these machines with basic skills, making them accessible for startups and small businesses.

Manufacturers design the control systems of compact paper bag making machines for ease of operation. Many models, such as the RZFD-190 Square Bottom Paper Bag Machine, feature intuitive touchscreen interfaces. For example, a French Schneider touchscreen allows operators to manage the entire process with a few taps. Clear menus and labeled buttons guide users through each step. This simplicity reduces the time needed for operator training. New workers can learn to use the machine quickly and with confidence. The risk of mistakes drops because the interface prevents confusion. Simple controls also help maintain steady production, as operators can monitor progress and make changes without stopping the machine.

Touchscreen panels display real-time information.

Operators can adjust settings with minimal effort.

Training sessions become shorter and more effective.

A simple paper bag-making machine supports fast and precise adjustments during operation. Operators use manual handwheels to change the depth of the bag inset, which controls the V-shape at the bottom. Screws can be loosened to slide or align molds, ensuring each bag has the correct shape and size. Wheels and rulers help with fine-tuning. Control buttons, including jog buttons, allow for small changes in paper feed and bag width. Pre-cutting knives can be adjusted to set the bag length. Some machines even offer wireless remote controls, so operators can start, stop, or jog the machine from a distance. Control panels with touchscreens or buttons let users change bag size, speed, and length while the machine runs.

Manual handwheels adjust bag inset depth.

Screws and molds allow for quick shape changes.

Jog buttons and remote controls enable safe, rapid adjustments.

Operators can respond to new orders or design changes without long delays, keeping production efficient and flexible.

Small paper bag making machines stand out for their low maintenance requirements. Manufacturers design these machines with fewer moving parts and robust construction. Operators can clean and inspect the equipment quickly. Most models use durable materials that resist corrosion and wear. This reduces the need for frequent repairs or part replacements. Many machines feature simple mechanisms, so operators can perform routine checks without special training. Low maintenance means less downtime and lower costs for small businesses. Owners can focus on production instead of constant repairs. Regular cleaning and basic lubrication keep the machine running smoothly. Some models even include self-lubricating components, which further reduce maintenance needs.

Tip: A low maintenance machine helps businesses meet tight deadlines and maintain consistent quality.

Energy efficiency plays a key role in modern compact paper bag making machines. Manufacturers focus on reducing operational costs and supporting sustainability. Many machines now include energy-saving technologies such as intelligent control systems and efficient motors. For example, the MASBOND MS-PB2 model uses advanced controls to minimize power consumption during production. It also supports the use of eco-friendly packaging materials, which aligns with sustainability goals.

Automatic machines often feature energy-saving modes that lower electricity use when the machine is idle. Oyang’s machines use high-precision core parts to reduce running resistance, which leads to lower energy consumption. Zhejiang Zenbo’s small paper bag machine includes automated controls for efficient operation and quick size changeover. These features help businesses save money and reduce their environmental impact.

Energy-efficient machines appeal to companies that value sustainability and want to meet regulatory standards. Lower power use also means reduced carbon emissions, which supports a cleaner environment. By choosing energy-efficient equipment, businesses can achieve their sustainability goals while keeping operating costs low.

Manufacturers design compact paper bag making machines with accessible service points. Operators can reach key components easily for cleaning, inspection, or minor repairs. Many machines feature removable panels or doors that provide quick access to belts, rollers, and cutting blades. Clear labeling and simple layouts help users identify parts that need attention. This design reduces the time needed for maintenance tasks. Operators do not need to disassemble the entire machine to fix small issues. Accessible service points support a low maintenance routine and help prevent unexpected breakdowns. Businesses benefit from longer machine life and more reliable production.

Note: Easy access to service points ensures that even small teams can keep the machine in top condition without hiring outside technicians.

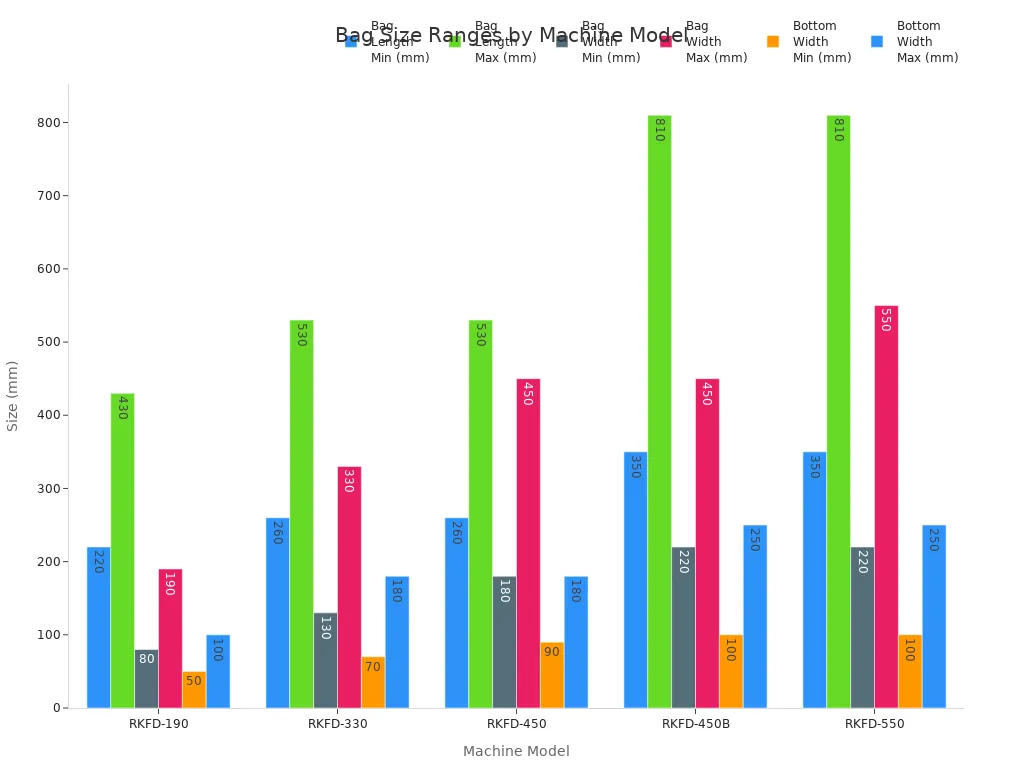

Compact paper bag making machines offer impressive flexibility through their adjustable settings. Operators can change the machine’s configuration to produce bags of different lengths, widths, and bottom sizes. For example, the RZJD-250 Food Grade Small Paper Bag Machine allows users to set bag lengths from 100mm to 450mm, widths from 70mm to 250mm, and insert sizes from 20mm to 120mm. This range supports the production of small bags for items like medicine or jewelry, as well as larger bags for groceries or clothing.

The following table shows the bag size ranges for several compact models:

| Model | Bag Length Range (mm) | Bag Width Range (mm) | Bottom Width Range (mm) |

|---|---|---|---|

| RKFD-190 | 220 - 430 | 80 - 190 | 50 - 100 |

| RKFD-330 | 260 - 530 | 130 - 330 | 70 - 180 |

| RKFD-450 | 260 - 530 | 180 - 450 | 90 - 180 |

| RKFD-450B | 350 - 810 | 220 - 450 | 100 - 250 |

| RKFD-550 | 350 - 810 | 220 - 550 | 100 - 250 |

These adjustable features let operators quickly switch between different bag sizes without changing machines. The adjustable bag sizes feature saves time and reduces the need for extra equipment. Operators can also adjust the machine to handle various paper thicknesses and feed widths, supporting a wide range of packaging needs.

Tip: Adjustable settings help small businesses serve more customers by offering bags for many uses, from bakery goods to electronics.

Bag size and format flexibility gives compact paper bag making machines a major advantage. These machines can create bags for many industries, including retail, food, pharmaceuticals, and e-commerce. Operators can use the adjustable controls to make bags that fit specific products, such as small pouches for medicine or large, sturdy bags for groceries.

Adjustable settings enable production of bags in various sizes and shapes, allowing customization for different industries.

Small bags can be made for pharmaceuticals, while larger bags suit groceries.

Custom features like ventilation holes help keep agricultural produce fresh during transport.

Reinforced handles and compartments can be added for textile industry packaging.

Specialty shops can design unique bags to enhance customer experience, demonstrating flexibility in production.

The table below highlights how different industries benefit from this versatility:

| Industry | Product/Application | Benefits/Features |

|---|---|---|

| Retail | Clothing, shoes, jewelry | Trendy printed bags with handles for branding and customer appeal |

| Pharmaceutical | Bottles, chemicals | Heavy-duty bags for safe transport; small stylish bags for pharmacies |

| Food Industry | Dry nuts, biscuits, cupcakes | Bags with windows for display, protection from dirt, increased shelf life |

| Grocery Stores | Fresh fruits and vegetables | Porous kraft paper bags keep produce fresh; handles for easy carrying |

| E-commerce | Custom-sized eco-friendly packaging | Flexible bag sizes, sustainable packaging for shipping |

The bags produced by these machines can carry up to 10kg, making them suitable for heavy items like flour, sugar, or chemicals. Strong kraft or card paper, combined with secure gluing, ensures durability and prevents leaks.

Note: Bag size and format flexibility allows businesses to adapt quickly to changing market demands and customer preferences. Operators can meet special requests without investing in new machinery.

Selecting the right compact paper bag making machine starts with a careful look at space requirements. Each machine type and production capacity needs a different amount of room. Operators must plan for more than just the machine itself. They should also allow space for raw material storage and finished product storage. A well-organized plant layout improves workflow and keeps the work area safe.

Operators should optimize the plant layout for efficiency and safety.

Separate areas for raw materials, production, quality control, and finished goods help keep operations smooth.

Planning for future expansion allows the business to grow without major changes.

A thoughtful approach to space ensures the machine fits well and supports efficient production.

When choosing a compact paper bag making machine, users should compare key features to match their business needs. The table below highlights important categories and what to consider:

| Feature Category | Key Considerations & Importance |

|---|---|

| Automation Level | Fully automatic machines offer high efficiency and speed, ideal for large-scale production; semi-automatic machines provide flexibility and control for smaller or specialized needs. |

| Material Compatibility | Ability to handle kraft, laminated, and grease-proof paper ensures suitability for different bag types and uses. |

| Size Flexibility | Machines adjustable to produce various bag sizes cater to diverse market demands and reduce the need for multiple machines. |

| Production Speed | Higher speeds improve output but must be balanced with quality and machine durability. |

| Energy Efficiency | Machines with servo motors can reduce energy consumption by up to 30%, lowering operational costs and environmental impact. |

| Maintenance & Durability | Ease of maintenance, repair frequency, and costs affect long-term reliability and budgeting. |

| Advanced Features | Automatic tension control, sealing mechanisms, flap creation, automatic feeding, and sensing technology improve efficiency and reduce labor. |

| Customization Options | Printing capabilities, handle attachments, and multi-functionality add value depending on branding and product needs. |

| Customer Support & Training | Comprehensive support and operator training ensure smooth operation and maximize machine investment. |

The global market for bag-making machines continues to grow, driven by eco-friendly packaging and e-commerce. Advanced machines now include smart technology for predictive maintenance and real-time monitoring. Energy-efficient models with servo motors help lower operational costs and environmental impact. These innovations improve efficiency, reduce labor needs, and minimize downtime. Operators should focus on features that support their production goals and maintain high product quality.

Budget plays a major role in selecting a compact paper bag making machine. Initial investments for these machines usually range from $21,000 to $23,000. Standard or larger models can cost between $58,000 and $350,000. Startups often spend between $30,000 and $120,000 to launch a paper bag manufacturing operation. The table below compares typical price ranges:

| Machine Type | Price Range (USD) | Notes |

|---|---|---|

| Compact Paper Bag Making Machine | $21,000 - $23,000 | Example: Kraft V Bottom Model XKJD-400 |

| Standard / Larger Models | $58,000 - $350,000 | Includes square bottom, flat bottom, high-speed machines |

| Startup Machinery Investment | $30,000 - $120,000 | Typical range for paper bag manufacturing startup costs |

Operators should balance cost with production needs and expected output. Compact machines offer a lower entry point, making them ideal for small businesses or startups. Investing in the right machine helps ensure long-term success and supports business growth.

Compact design features play a vital role for small paper bag making machines, especially in tight spaces. Users should focus on these priorities:

Choose a small footprint and lightweight build for easy placement and movement.

Select user-friendly controls and advanced features for efficient operation.

Opt for modular, multifunctional layouts to maximize space and flexibility.

Matching machine features to business needs improves outcomes. For example:

| Machine Feature | Business Need Addressed |

|---|---|

| Bag Dimensions Support | Meets market demands and sustainability |

| Automation Level | Reduces labor and boosts productivity |

Selecting the right features helps small businesses grow and succeed.

Most small machines measure between 7 and 9.6 meters in length and about 3 meters in width. These dimensions allow easy placement in small workshops or home-based businesses.

Yes. One person can usually operate these machines. The user-friendly interface and simple controls make training easy. Many small businesses rely on a single operator for daily production.

Most compact machines use single-phase power. They consume less electricity than larger models. This helps small businesses save on energy costs and supports eco-friendly production.

Compact machines work with kraft paper, laminated paper, and grease-proof paper. Operators can adjust settings to match different paper thicknesses and qualities.

Manufacturers design these machines for low maintenance. Regular cleaning and basic lubrication keep them running smoothly. Most operators perform simple checks weekly.

Yes. Operators can adjust the machine to create bags of various lengths, widths, and bottom sizes. This flexibility helps businesses serve many industries.

Many compact machines offer advanced features. Options include photocell registration, ServoTech, and handle attachments. These features improve bag quality and add value for customers.

Most small machines have wheels or handles. Operators can move them easily for cleaning, maintenance, or layout changes. This mobility supports flexible production spaces.