- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-30 Origin: Site

Valve bag making machines have transformed rapidly in recent years. The global valve bag market reached $1.5 billion in 2024, with North America leading and Asia-Pacific showing the fastest growth. Manufacturers now face increasing pressure to produce valve cement bags with greater efficiency, durability, and environmental responsibility. Advanced robotics, AI-driven vision systems, and digitalization lead these trends, raising expectations for both manufacturers and end-users. As demand for high quality valve bag making machine price transparency rises, companies look for smart solutions to stay ahead. Valve cement bags continue to set new standards in packaging performance and sustainability.

Valve bag making machines continue to evolve as manufacturers seek greater packaging efficiency, sustainability, and reliability. The industry now sees a strong shift toward advanced automation, smart sensors, and eco-friendly materials. These trends shape the future of valve cement bags making machines and drive innovation in industrial packaging.

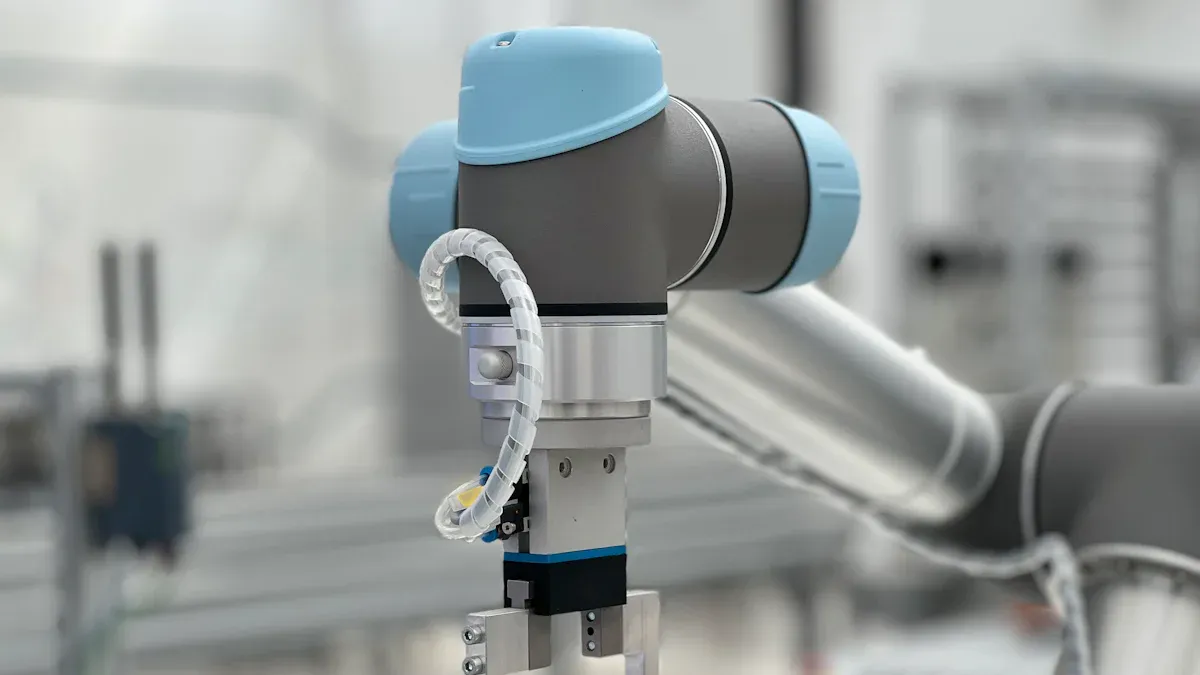

Manufacturers now rely on automation to streamline production and reduce manual labor. Valve bag making machines feature robotic automation for bag filling, placing, and palletizing. These systems handle tasks such as bag closing, sealing, and sewing with high precision. Modern machines include components like kickers, turners, conveyors, and flatteners to improve packaging efficiency and consistency.

Robotic automation in valve bag filling and placing

Industrial automated controls integrated with robotics

Robotic palletizing systems for end-of-line automation

Bag closing, sealing, and sewing systems

Bag handling components such as kickers, turners, conveyors, and flatteners

Modular and scalable designs enhancing operational flexibility

Cloud connectivity for monitoring and downtime reduction

Bosch introduced an automatic robotic FFS bagger in late 2023, increasing throughput by 12%. All-Fill enhanced 25% of its 2024 models with cloud monitoring, reducing downtime by 7%. Valve baggers with density-control for powders launched in 2024, improving filling accuracy by 9%. Modular and scalable designs now support small and medium-sized enterprises, making advanced automation more accessible.

Valve cement bags making machines now use advanced control systems to synchronize operations. These systems integrate robotics and vision technology, allowing real-time adjustments and quality checks. About 18% of new machines feature robotics and vision systems, while 25% offer cloud connectivity. Nearly half of new machines support eco-friendly packaging, reflecting the industry's commitment to sustainable packaging solutions.

Smart sensors and IoT technology have become standard in valve bag making machines. These features enable real-time monitoring of machine performance, product quality, and operational status. Operators receive instant alerts about potential issues, which helps prevent downtime and maintain high packaging efficiency.

Note: Real-time analytics and cloud connectivity allow manufacturers to track every stage of valve cement bags production, ensuring consistent quality and reducing waste.

Predictive maintenance uses AI algorithms and IoT sensors to detect wear and tear before failures occur. Valve cement bags making machines equipped with these technologies can schedule maintenance only when needed, reducing unnecessary downtime and extending equipment life. All-Fill’s cloud monitoring reduced downtime by 7% in 2024, showing the value of predictive maintenance in industrial packaging.

Energy-efficient bag making machines now dominate the market. Manufacturers design machines to minimize power consumption and optimize production cycles. High automation enables synchronization between tuber and bottomer systems, reducing manual labor and energy use. Quick-change modules, tool-free adjustments, and self-cleaning systems further enhance operational efficiency and waste reduction.

The shift to eco-friendly materials marks a major trend in valve cement bags making machines. Producers now use recyclable and non-toxic polypropylene (PP) materials, as well as biodegradable plastics and recycled fabrics. Machines can handle virgin kraft paper, recycled paper layers, PE-coated paper, and BOPP films. Modular designs allow upgrades to biodegradable or compostable layers, future-proofing production for sustainable packaging solutions.

Use of recyclable and non-toxic PP materials in valve bag production

Implementation of recycling machines enabling recovery and reuse of waste bags

Alignment with United Nations goals for responsible consumption and production

Flexibility to handle eco-friendly materials such as biodegradable plastics and recycled fabrics

Optimization for eco-friendly valve bag production using recyclable paper composites and solvent-free adhesives

Valve cement bags now meet strict environmental standards, supporting the global push for responsible consumption. The integration of Industry 4.0 technologies, such as SCADA systems and real-time analytics, further boosts sustainability and operational reliability.

Manufacturers recognize that the future of valve bag making machines lies in combining automation, IoT, and sustainable practices. The industry’s focus on packaging efficiency, eco-friendly materials, and advanced automation ensures that valve cement bags making machines remain at the forefront of industrial packaging innovation.

Manufacturers now use advanced data analytics and artificial intelligence to optimize high-speed production. Industrial Internet of Things (IIoT) networks connect machines and software, allowing real-time data collection and analysis. Big Data tools extract valuable insights from large volumes of production data. Cloud computing supports scalable storage and remote monitoring, while edge computing processes information near the source for faster response times. These technologies help operators make better decisions, reduce downtime, and improve efficiency.

IIoT networks enable predictive maintenance and real-time monitoring.

Big Data analytics support smarter decision-making.

Cloud and edge computing enhance responsiveness and scalability.

Digital twins provide virtual models for safe testing and process improvement.

Autonomous robots increase precision and adaptability in manufacturing.

Servo-driven systems and advanced controls adjust machine parameters instantly, supporting high-speed production and consistent quality. Flexible machinery platforms allow quick changes for different bag sizes and materials, making valve bag making machines more adaptable to market needs.

Artificial intelligence and machine learning now enable systems to learn from data and improve over time. These technologies support personalized packaging by adjusting settings for each production run. Operators can quickly reconfigure machines to handle custom orders or new materials. Remote diagnostics and aftermarket analytics help maintain performance and reduce costs. Training skilled technicians in robotics and data analytics ensures effective use of these advanced features.

Smart packaging features have become essential in modern valve bag making machines. Digital tools such as QR codes, sensors, NFC tags, and RFID systems enable real-time information sharing. These connected devices communicate product condition and movement throughout the supply chain. Integration with ERP and MES systems ensures a continuous flow of data, supporting timely decisions and efficient inventory management.

Smart packaging systems improve product tracking and supply chain transparency. The table below highlights key technologies and their functions:

| Smart Packaging System | Function | Contribution to Product Tracking and Supply Chain Transparency |

|---|---|---|

| O2 Sense TM, Novas®, Ageless Eye® | Integrity indicators | Monitor package integrity to ensure product quality during transit |

| Freshtag®, Sensorq® | Freshness indicators | Provide real-time freshness status, aiding quality control |

| Timestrip Complete® | Time-temperature indicators | Track exposure to temperature over time, ensuring proper storage |

| Easy2log®, Intelligent Box, CS8304, Temptrip | RFID systems | Enable real-time tracking and inventory management across the supply chain |

These technologies allow continuous monitoring and communication, enhancing traceability and transparency. Blockchain integration further strengthens quality control and supply chain visibility.

Emission control remains a priority for manufacturers. Advanced filtration systems capture dust and airborne particles during high-speed production. These systems protect workers and the environment by maintaining clean air in the facility. Innovations in sealing and bag handling also support the use of biodegradable and lightweight materials, reducing the environmental impact of valve bag making machines.

Manufacturers must meet strict compliance standards for emissions and sustainability. Real-time data analytics and machine learning help monitor emissions and ensure adherence to regulations. Remote monitoring and diagnostics support continuous improvement and reduce the total cost of ownership. Companies that invest in automation and emission control technologies gain a competitive edge in the global market.

Manufacturers have made significant progress in the durability of valve bag making machines since 2022. They now use advanced materials such as polyethylene, polypropylene, and woven fabrics. These materials increase strength and wear resistance, allowing bags to withstand rough handling and long storage periods. Automated manufacturing processes also play a key role. Machines now deliver precise sealing, which reduces defect rates and ensures each bag maintains its integrity during transport. Detector sensing systems monitor every seal, catching errors before they reach the end of the line. This focus on quality control leads to more robust and reliable bags.

Modern valve bag making machines incorporate advanced design components that improve valve placement accuracy. High-precision sensors and automated controls ensure each valve is positioned correctly, minimizing the risk of leaks or product loss. Consistent valve placement supports high-quality output, especially in demanding industrial environments where reliability is critical.

Today’s machines offer a wide range of customization options, making it easier for manufacturers to meet specific client needs. Quick-change features allow operators to adjust bag sizes, valve placements, and printed designs with minimal downtime. The table below compares modern valve bag making machines with traditional equipment:

| Feature | Modern Valve Bag Machines | Traditional Equipment |

|---|---|---|

| Customization | Quick changes in bag sizes, valve placements, and printed designs with minimal downtime | Requires extensive retooling and manual effort |

| Material Waste | Optimized cutting and adhesive application to minimize waste | Higher scrap and waste due to less precision |

| Energy Efficiency | Designed for lower energy consumption while maintaining high speeds | Higher power consumption |

| Labor Requirements | Automation reduces manual labor needs | More hands-on operation required |

| Production Speed | High-speed, automated processes | Slower, more manual intervention |

| Precision | Consistent dimensions and accurate gluing | Prone to variations and inconsistencies |

Manufacturers have re-engineered machines to include 60% fewer moving parts, which reduces maintenance and downtime. New features such as robotic bag applicators, real-time seal detection, and high-speed air packers make operation smoother and cleaner. The design supports easy cleaning and requires minimal operator training. Rugged construction ensures long-term reliability, while the ability to handle a wide range of materials—including powders, grains, and chemicals—adds to operational flexibility.

Valve bag making machines now feature efficient workflows that lower operating costs by minimizing downtime. Automated controls and faster filling cycles help maintain product quality and reduce waste. Precision control over material usage and optimized cutting processes further minimize excess trimmings, supporting both cost savings and environmental sustainability.

Tip: Versatile machines that accommodate various materials help reduce unnecessary material use, making packaging operations more sustainable.

In 2025, manufacturers design machines to process eco-friendly materials such as recyclable plastics, biodegradable papers, and woven fabrics. Lightweight designs reduce raw material consumption, while precise filling and sealing processes minimize waste and spillage. Many machines now enable compliance with global sustainability standards and incorporate energy-efficient technologies, including solar-powered operations and biodegradable films. These innovations help companies meet growing demands for sustainable packaging.

Manufacturers now focus on energy savings to improve the high quality valve bag making machine price. Modern machines use advanced motors and smart controls to reduce electricity consumption. These upgrades help companies lower their monthly utility bills. Energy-efficient systems also support sustainability goals by reducing the carbon footprint of production. Operators notice that machines with lower energy needs run cooler and last longer. This approach not only saves money but also extends the life of the equipment.

Material optimization plays a key role in controlling the high quality valve bag making machine price. New machines use precise cutting and sealing technologies to minimize waste. Automated systems measure and adjust material usage in real time. This reduces scrap and ensures each bag meets quality standards. Companies benefit from lower raw material costs and less waste disposal. The following list highlights how cost efficiency improvements impact total cost of ownership:

Fully automatic machines have higher upfront costs but reduce labor expenses over time.

Automation and energy efficiency lower operational costs and machine downtime.

Total cost of ownership includes installation, training, maintenance, and downtime over several years.

Cost efficiency improvements cut labor, maintenance, energy, and downtime expenses.

Lower total cost of ownership leads to faster returns and more sustainable operations.

Maintenance reduction directly affects the high quality valve bag making machine price. Advanced machines feature fewer moving parts and self-diagnostic systems. These features help operators spot issues early and schedule repairs before breakdowns occur. As a result, companies spend less on emergency repairs and replacement parts. Strong after-sales support and durable construction further reduce maintenance costs. This reliability keeps production lines running smoothly and boosts overall profitability.

Long-term value remains a top priority for buyers considering the high quality valve bag making machine price. Manufacturers look for machines that offer flexibility, speed, and adaptability. Compatibility with different bag sizes and materials allows quick changeovers and supports future growth. High-speed machines increase output and reduce labor costs. Automation improves accuracy and minimizes downtime. The table below summarizes key factors influencing return on investment:

| Factor | Impact on ROI |

|---|---|

| Machine speed | Increases output and reduces labor costs |

| Automation | Improves accuracy and consistency |

| Durability and support | Lowers maintenance and extends service life |

| Customization and scalability | Adapts to changing production needs |

| Total cost of ownership | Optimizes long-term profitability |

Tip: Companies that consider total cost of ownership—including energy, spare parts, labor, and downtime—achieve better long-term value and maximize their investment.

Manufacturers who invest in advanced valve bag making machines see improved packaging efficiency and a stronger competitive position. The right balance between initial investment and ongoing savings ensures the best high quality valve bag making machine price for sustainable growth.

Construction and infrastructure drive the highest adoption of valve cement bags making machines. Cement producers and building material suppliers rely on these machines for reliable, high-volume packaging. The demand for valve cement bags continues to rise as urbanization accelerates and large-scale projects expand. Manufacturers in chemicals and minerals also invest in valve cement bags making machines to protect products from moisture and contamination. The food and agriculture sectors use valve cement bags for bulk goods, benefiting from the machines’ flexibility and efficiency.

Asia Pacific leads global growth in valve cement bags making machines. Rapid urban development and infrastructure investments in China, India, and Southeast Asia fuel this expansion. North America and Europe maintain steady demand, focusing on automation and sustainability. Africa and Latin America show emerging interest as construction activity increases. Regional manufacturers seek machines that offer high-speed production and adaptability to local market needs.

Early adopters of advanced valve cement bags making machines gain significant advantages. Automation reduces manual labor and errors, boosting productivity. AI integration enables predictive maintenance and real-time quality control, minimizing downtime. IoT connectivity allows centralized monitoring and process optimization, increasing operational agility. Companies that invest early in these technologies respond faster to market changes and meet the growing demand for customizable valve cement bags.

Valve cement bags making machines deliver high-speed production, reaching up to 130 bags per minute. This capability meets large-scale demands and improves profitability. Advanced automation, including AI visual inspection, ensures only high-quality valve cement bags reach customers. Patented technologies, such as triangle bag opening, create stable and efficient bag formation. Durable PP woven valve sacks protect cement during transport and storage. Flexible customization options allow manufacturers to meet diverse customer requirements, enhancing satisfaction and loyalty.

Note: Precision sealing and valve formation ensure airtight, moisture-resistant valve cement bags, protecting product quality and reducing material loss.

Manufacturers should select technology partners with expertise in automation, AI, and IoT integration. Collaborations foster innovation and support the development of modular, scalable valve cement bags making machines. Leading partners offer strong after-sales support, training, and access to the latest advancements in industrial packaging.

Companies planning to invest in valve cement bags making machines must align machine capacity with operational scale. Low-capacity machines suit small operations, while high-capacity models serve large enterprises. Rotary and valve packing machines dominate due to efficiency and speed. Technological advancements, such as vacuum and air packing, improve packaging precision. Manufacturers emphasize eco-friendly, energy-efficient, and customizable machines to meet evolving market demands. Integration of smart technologies supports predictive maintenance and operational efficiency.

| Investment Factor | Recommendation |

|---|---|

| Automation Level | Prioritize automatic machines for higher output |

| Machine Capacity | Match to business scale (small, medium, large) |

| Technology Integration | Seek AI, IoT, and modular design |

| Sustainability | Choose energy-efficient, eco-friendly machines |

| Partner Collaboration | Work with experienced technology providers |

Current trends in valve cement bags packaging highlight the shift toward sustainable materials, smart packaging, and advanced automation. These trends shape the future of valve cement bags making machines, ensuring they remain essential in industrial packaging.

Manufacturers see major benefits from adopting advanced valve bag making machines. Key innovations include automation, smart sensors, and sustainable materials. Strategic advantages arise from Bag On Valve technology, which supports eco-friendly, hygienic, and efficient packaging across industries.

Next steps for manufacturers:

Assess material compatibility and production needs.

Prioritize safety, dust control, and ease of maintenance.

Plan for scalability and future upgrades.

Staying informed and investing in new technologies helps companies boost efficiency, meet sustainability goals, and remain competitive in a changing market.

A valve bag making machine produces industrial bags with a valve opening. These bags allow for quick filling and secure sealing. Manufacturers use them for packaging cement, chemicals, and food products.

Automation increases speed and accuracy. Robots handle repetitive tasks, reducing errors and labor costs. Automated systems also monitor quality and adjust settings in real time.

Industries such as construction, agriculture, chemicals, and food processing benefit most. These sectors require durable, high-volume packaging for bulk materials.

Modern machines handle a wide range of materials:

Polypropylene (PP)

Polyethylene (PE)

Kraft paper

Biodegradable films

Note: Machines often support both recyclable and compostable options.

Smart sensors track machine status and product quality. They send alerts for maintenance needs and detect faults early. This technology reduces downtime and improves efficiency.

Manufacturers design new machines for energy efficiency and low emissions. Many models use recyclable or biodegradable materials. Companies can meet global sustainability standards with these machines.

| Factor | Impact on Price |

|---|---|

| Automation Level | Higher automation costs more |

| Material Compatibility | Versatile machines cost more |

| Production Speed | Faster machines cost more |

| Sustainability Features | Eco-friendly options add cost |

Most advanced machines need maintenance every 6 to 12 months. Predictive maintenance features help schedule service only when necessary, reducing unexpected downtime.